Walk In Coolers

Products » Walk In Coolers

KPS Global® is the leading provider of custom walk in coolers for a variety of industries

From convenience stores, dollar stores, grocery stores, and warehouse club stores, our custom walk-ins are built to spec and set the standard in the industry.

Our experienced, in-house design and engineering teams give you access to knowledgeable resources so your project is built to your specifications. KPS Global® walk-in coolers are built with HFC-Free polyurethane foam and offered in three frame types as well as a variety of finishes.

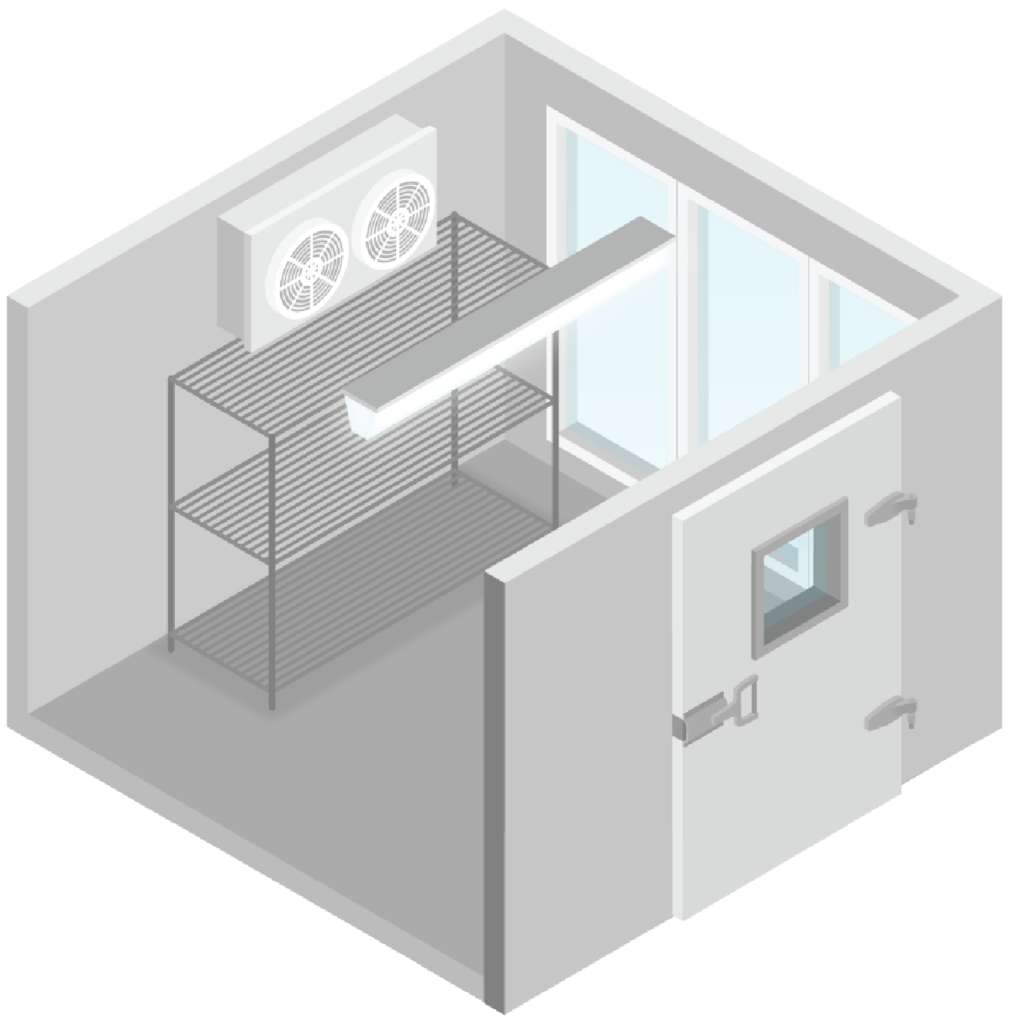

What is a Walk-in Cooler?

A walk-in cooler is a large refrigerator with access to the inside of the unit where product is stored between 33 and 38 degrees Fahrenheit. The difference between a reach-in cooler and a walk-in cooler is that a walk-in cooler has an access point for the product to be stocked or merchandised from inside the unit, whereas, a reach-in cooler is a self-contained unit with only display doors to both access and load product from the front of the unit.

Examples of walk-in coolers used in a typical grocery store would be dairy coolers, bakery coolers, meat/poultry/seafood coolers, produce coolers, floral, beverage coolers, deli coolers and prepared foods coolers. To understand how a walk-in cooler works, click here.

Panel Construction

Walk-in cooler panels vary from custom to nominal sizes and with various insulation options. The superior insulation material is polyurethane foam. Click Here for a Comparison of Foam Types.

KPS Global constructs walk-in coolers using a 3 ½” or 4” thickness panel with poured-in-place polyurethane foam. The panel has a tongue-and-groove profile with three frame options: wood, foam or hybrid. The panels fasten together using a cam-lock system with a gasket, that along with butyl, keeps water vapor out of the unit. This is key to performance over time.

Many manufacturers of walk-in coolers only offer a limited number of unit sizes with a predetermined height or width. This is often called nominal sizing. While there are some manufacturing advantages to this, there are limitations to this sizing approach in construction projects with streamlined store layouts for efficient operations. Not being able to locate two units next to each other creates inefficiencies in construction layouts or could disrupt business operations compared to custom-sized units that can be sized to fit the space, For example, if a retailer wanted a prep cooler near the deli counter but a nominal-sized unit is too large for that space, then the grocery layout may need to be reconfigured. Whereas a custom-sized walk-in cooler can be made to fit the exact dimensions.

As a custom manufacturer of walk-in coolers, KPS Global panels are made in the USA and constructed to exact sizes instead of nominal dimensions. The benefits of having a custom walk-in cooler include optimizing the store layout and being able to maximize the refrigeration capacity.

Controlling the Conditions

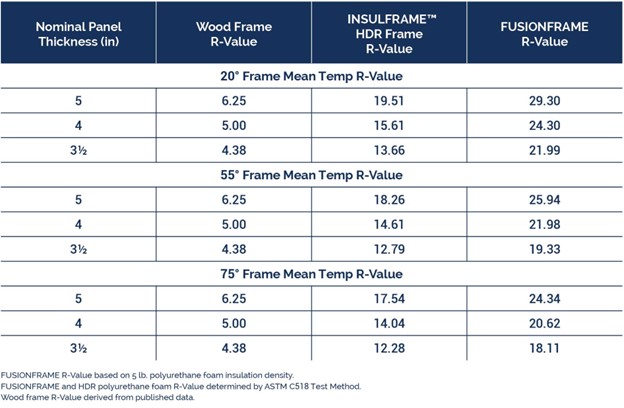

The high-quality panel construction of walk-in coolers allows the operator to control the environment (ie: specific temperature or humidity levels depending on the product being stored). R-values measure how well our various panel options resist the flow of heat. The higher the R-value, the more resistance a panel has to heat flow, allowing it to have better insulating properties. The R-values of KPS Global panels varies based on application and panel thickness. The below chart shows an example of various R-values for our standard walk-in cooler frame types.

As a manufacturer of walk-in coolers, KPS Global offers superior build standards from five manufacturing locations across the country with in-house design and engineering for your project.

Outdoor Walk-in Coolers

Often, a retailer or restaurant will need cold storage but do not have the physical space to locate a walk-in cooler indoors. Outdoor walk-in coolers are quite common but do have additional requirements when designing. These differences between indoor and outdoor walk-ins are important and should be considered during the design process.

Roofing and flooring are required for outdoor walk-in coolers as well as other location specific needs.

Outdoor walk-ins make loading and unloading easier – you can bring products directly into the unit without having to worry about staff members disrupting the workflow of the building.

The biggest advantage of an outdoor walk-in refrigeration unit is that it allows for a quick and easy installation that avoids disrupting store operations. Refrigeration units can easily be placed and installed, and an outdoor location essentially eliminates the need to set up ventilation and refrigerant lines in your building.

Custom Walk-in Cooler Options

Walk-in coolers can have many customization options from cosmetic elements like metal color to incorporating store design layouts like display doors or access doors for combo boxes.

From traffic doors to display doors, to high-speed rollup to walk-in doors, there are several options to consider when laying out and designing your custom walk-in cooler. The location of the structural support and placement in the overall design is key. KPS Global does not manufacture glass or traffic doors but regularly incorporates them into the overall design of the walk-in cooler. It’s often easier to think about a specific application when designing coolers. For example, the floral cooler. It is often located on the store floor or adjacent to the sales floor. There is a need for merchandising and yet keeping the flowers at optimal temperature. Customers need to then be able to select the display and continue their shopping. Glass display doors are the perfect solution here. But much like a convenience store beverage display, loading the product is much easier to do from behind. That is where a walk-in cooler is a better solution than a reach-in case. Loading and accessing product is significantly easier when you can walk into a cooler.

The key to designing custom walk-in coolers is to consider the use and function of the unit in the design stage. Here are some components frequently used in walk-in coolers:

• Glass Display Doors

• Traffic Doors

• Strip Curtains

• Windows/Viewports

• Additional Doors/Access Points

• Alarms

• Lighting

• Shelving

• Bollards

For convenience stores, having the ability to have a multi-door line up is critical to the success of the store. Efficiencies gained from loading and stocking the unit from within the walk-in cooker make the multi-door line up profitable. Many retailers also want to incorporate view ports, or windows, into the walk-ins. These are all easy to incorporate but require knowing your requirements on the front end, so they are included in the design of the walk-in cooler units.

Considerations when Designing Walk-in Coolers

The geographic location of the store is something that also has to be considered during the design phase. If a store is located in a seismic or hurricane zone, then additional structural elements need to be added to the walk-in cooler or freezer. Often times, the walk-in becomes an integrated piece to the store floor. From shopping doors to advertising space.

Most walk-in coolers do not have a floor. However, like anything else there are exceptions. KPS Global has the ability to provide a floor for your walk-in cooler if needed. For example, if a walk-in cooler is installed above the grade or on the 2nd or 3rd floor. A walk-in cooler floor is constructed in the same way as the wall panels but with the addition of a substrate for support based on intended use and load requirements.

Ramps are another helpful addition to a walk-in cooler and make the unit easier to load. Ramps for walk-ins can be inside the unit or external to the unit. The decision of where to locate a ramp is often dependent on space but also should take into account the amount of traffic the floor will be taking, including the type of product being stored and the tool used to maneuver the product inside the walk-in cooler.

Protecting your Walk-in Cooler

Walk-in coolers are one of the most expensive pieces of equipment in a commercial kitchen or retail food store. They take a lot of abuse and yet have a critical job to do. Protecting a walk-in cooler is often easier than you may think.

Frequently Asked Questions

A walk-in cooler can be any size or shape and is not limited to a specific shape or nominal sizes.

Whether the unit is in a coastal, hurricane or seismic location is critical and drives structural needs that should be designed into the unit so that your walk-in cooler performs optimally in its environment.

The location of your walk-in cooler absolutely impacts the final design considerations. Please disclose the location of the unit when requesting a quote.

Knowing the type of product the unit will hold, as well as the purpose (storage or processing) helps in the design process and defines the specifications.

Will a window or viewport be needed? Will it be a combo box? Will strip curtains be needed? What lighting will be needed? Shelving? Alarms? Additional access points? These should all be identified up front in the design process.

How does a walk-in cooler work?

A walk-in cooler is a unit constructed of insulated panels made to resist the flow of heat. They are kept cold by refrigeration systems removing heat from one region and depositing it in another. Refrigeration systems function using the principles of pressure, condensing and evaporation of a fluid (the refrigerant) in a closed circuit to remove heat and reduce the temperature inside the walk-in.

What are the pros/cons of the various frame options on walk-in coolers?

For hard-nose panels, there are three frame options available:

• Wood

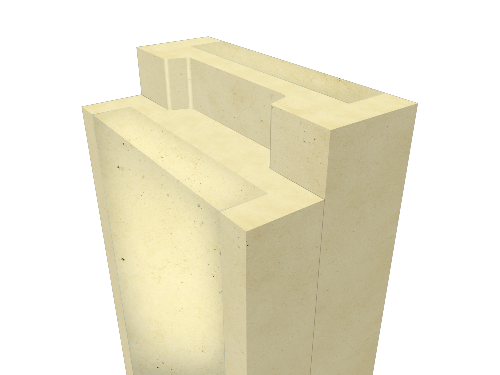

• Foam

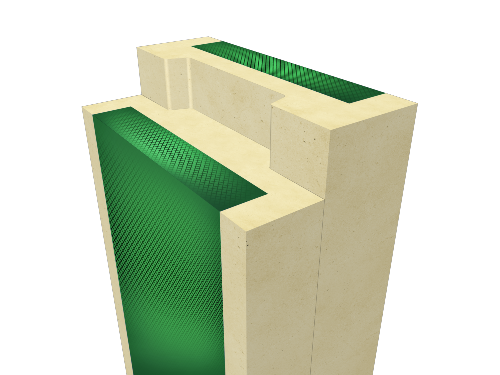

• Hybrid

Wood frames are traditionally the least expensive frame type and provide structural support.

Frames made of high-density foam provide a higher thermal value. KPS Global uses INSULFRAME™ which is the same polyurethane foam as the core of the panel but poured at a much stronger density, creating a stronger, more dense foam. Panels made with FUSIONFRAME® offer the structural performance of a wood-framed panel with the thermal performance of a foam frame.

What's in a Walk In Cooler?

Hover over the icons to learn more!

Lighting 1 of 5

Lighting 1 of 5

Refrigeration 2 of 5

Refrigeration 2 of 5

Shelving

3 of 5 Windows/Viewports 4 of 5

Windows/Viewports 4 of 5

Door Types

Walk-in Cooler Doors

Display Doors

Traffic Doors

KPS Global® has your Walk-In Cooler needs covered.

Request a quote today to get started.

Whether you need general information or have specific questions, we want to hear from you.

Not exactly sure where to start? One of our knowledgeable sales representatives can guide you through the process. Schedule a time to talk.