FAQ

Resources » FAQ

Frequently Asked Questions When Buying a Walk-In Cooler or Freezer

Buying a Walk-In Cooler or Freezer can be overwhelming. Help is here in this Q&A page where you can learn more about researching your needs, defining project specifications and getting a quote, the delivery and installation as well as maintenance of your walk-in.

Researching Your Needs

Does KPS Global offer different finishes or colors?

What type of projects and industries does KPS Global have experience in for providing design, manufacturing and installation?

How are KPS Global panels constructed?

KPS Global panels are constructed of two metal skins which sandwich a frame system and poured-in-place polyurethane foam. Panel frames can be wood or high-density foam and lock together with cam-locks.

What type of foam are your panels made with?

What is the R-Value of Polyurethane foam?

It all varies based on application and panel thickness. Check out the chart below that shows the R-Value of polyurethane panels in the various applications. In general, the R-Value of a walk-in freezer is 8.06 per inch foam thickness. The R-Value of a walk-in cooler is 7.19 per inch foam thickness and the R-Value of a walk-in in ambient environment is 6.71 per inch foam thickness.

| Application | R-Value per Inch Foam Thickness | 3 ½” Nominal Thickness | 4” Nominal Thickness | 5” Nominal Thickness |

| Freezer | 8.06 | 28.21 | 32.24 | 40.3 |

| Cooler | 7.19 | 25.17 | 28.76 | 35.95 |

| Non-Refrigerated | 6.71 | 23.49 | 26.84 | 33.55 |

NOTE: Required R-Values vary based on applicable regulations and temperature ranges.

Are KPS Global products compliant with NSF requirements?

Where can I get more information about the components KPSG offers?

We have a variety of component offerings that are available to purchase from KPS Global including refrigeration, lighting, shelving and more. All the options are listed at https://kpsglobal.com/products/components/ and one of our experts can help you with all your project needs.

What happens if I need a replacement part after I’ve bought my walk-in cooler or freezer?

What if I only need a replacement door for my walk-in cooler or freezer?

What if I need to remodel an existing walk-in cooler or freezer that is from another manufacturer?

Remodeling an existing walk-in is quite an undertaking and can be overwhelming. KPS Global has a turnkey contracting team that can handle everything about this replacement for you. With a single point of contact, a KPS Global employee will oversee the entire process including scheduling, contractors, walk-in panels, refrigeration, electrical etc.

Is a quick ship option right for me or do I need a custom solution?

What if I need assistance in determining what I need at an existing site?

KPS Global can send out a field tech to survey the location to get exact measurements and outline the requirements of the project for walk-in cooler panel replacement.

Are you located in my area?

KPS Global has three, strategically-located manufacturing plants across the country. KPSG also has field techs and installation crews located across the country to assist you with surveys of existing sites or installation or turnkey projects.

Thinking About Getting a Quote?

How much information do I need to have to get a quote? Can I request very specific measurements and requirements?

Should I request a quote even if I’m not totally sure about project details yet?

If you are still gathering the requirements of your project, it is best to finalize those before requesting a quote. That way the information you get from KPS Global will meet the needs of the job. We are happy to help with all the design and engineering requirements once those are determined. We also have refrigeration sizing specialists on staff who can help you determine the appropriate type of refrigeration you would need for your job. Bottom line – KPS Global has a team of in-house experts here to help!

How long does it typically take to get a quote back?

Depending on the complexity of the quote, turnaround times for walk-in coolers and freezers or insulated panel systems for industrial application quotes can range from 1-7 business days. KPS Global works with other manufacturers for components such as refrigeration and lighting where quotes could take longer to obtain (but it is important to note that this is typically for highly specialized or customized projects)

What goes into the pricing and the specifications of my quote?

The application and project specific needs of your insulated panel system drive the requirements for the project. Pricing is driven by the metal finishes, thickness and type of panel needed as well as other various components from OEMs.

Can I make special requests in my quote?

Do you offer models without floors?

Yes, based on your needs we offer models both with and without flooring options. When choosing a cooler with or without a floor, there are several factors to consider:

How Much Floor Traffic is Expected

If your cooler, or freezer, will experience fairly heavy foot traffic (heavy transporting units, hand trucks, pallet jacks, or heavy shelving with point loads) a standard aluminum floor may not hold up as well as concrete. In this case, you may want to consider instead installing over concrete for durability. However, the concrete will typically still need to be insulated to prevent ice from forming under the slab and causing damage.

The Location of Your Walk-In

If your walk-in is located in a warmer area, above the ground floor, or above a basement, the natural insulation of the floor and surroundings may not be enough to keep temperatures even, and can even cause moisture to build and damage existing flooring, ceilings, or even the concrete. In this case, insulated flooring may be required—speak to your KPS Global team today to help figure out what’s best for your install. There are several added benefits of installing a walk-in with insulated flooring. Some building leases do not allow for slab alterations, so the insulated floors can be designed for greater compressive strength. This can extend the life of your compressor since it doesn’t have to work so hard, will provide a better thermal envelope, and will be built to NFS standards which is especially important in foodservice applications where sanitation is key.

Talk to KPS Global today to determine which type is right for you. With the proper type of floor, you can protect not only your walk-in components but your establishment!

Delivery and Installation

How long is average order ship time? Is this time affected by location?

KPS Global has three, strategically-located manufacturing plants across the country which allows for several benefits. Operating off a single schedule, KPSG can look out over all three plants capacity and schedule jobs according to project timelines, location and available manufacturing space. This offers customers the benefit of building a walk-in for the West Coast out of our Goodyear, AZ location and a walk-in for Florida out of our TN location. Managing off a single schedule also allows KPS Global to level out demand therefore offering a consistent lead time of 3-4 weeks year-round. Specialty products or finishes do require additional lead times which vary according to the item but probably better to plan on a longer lead time for the specialty item.

Can KPS Global arrange the installation of my project?

Yes, KPS Global offers installation services for new walk-in coolers and freezers. KPSG leverages a nationwide database of contractors who can install the panels with a single point of contact managing the process.

Who does the installation?

Installation is managed by a KPS Global employee that deploys a crew of factory-trained installers who will erect your panel system according to specifications.

What if I need an entire project to be managed by someone?

Is turnkey service by a KPS Global certified team backed up by warranty?

Turnkey jobs typically have several trades involved and as such, KPS Global relies on the support of those trades/OEMs for their warranties. KPS Global offers a 1-year warranty on panels installed by a certified KPS Global contractor.

Maintaining Your Walk-In Cooler or Freezer

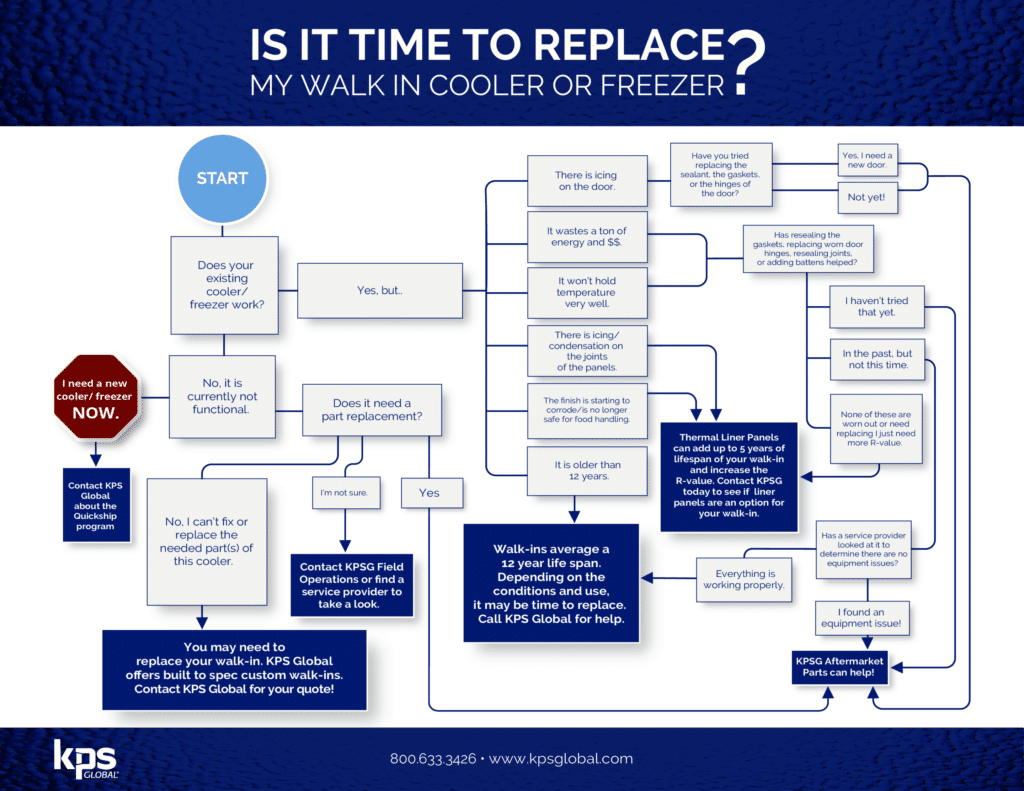

How do I know when to replace my walk-in cooler or walk-in freezer?

We’re glad you asked! We specifically designed this infographic to walk you through that difficult decision. Don’t forget to reach out to us if you’re unsure about your next steps—the infographic makes a great general guideline, but our experts can help you make sure you’re on the right path.

How frequently should I inspect the sweep gasket on my walk-in cooler or freezer door?

KPS Global recommends inspecting the sweep gasket monthly for ease of operation. It must be adjusted to allow free movement and proper seal. Any damaged hardware should be replaced immediately to prevent permanent damage to the door.

How frequently should I inspect the door hardware on my walk-in cooler or freezer door?

KPS Global recommends inspecting the sweep gasket monthly for ease of operation. It must be adjusted to allow free movement and proper seal. Any damaged hardware should be replaced immediately to prevent permanent damage to the door.

What does frost or condensation appearing around the door jamb indicate?

How do I clean my walk-in cooler or freezer?

All metal surfaces, magnetic door gasketing and door sweep gasket should be cleaned frequently with a mild detergent and hot water. Remove all soap film and dry thoroughly with a clean cloth. Never use high pressure hose or large amounts of water to clean walk-ins. Never use acetones or paint thinners.

For more recommendations, please see: https://kpsglobal.com/resources/installation-and-maintenance/