Artic Case Study

What is it?

Arctic Express Pack is a fully automated gel pack production system that is installed at end users’ facilities. The patent-pending technology allows the production of gel packs on-demand, maintain desired/specified gel pack temperatures, significantly reduce required storage and freezer space, and reduces transportation and labor cost, all while reducing their carbon footprint by up to 97%. The unit had three key design considerations: footprint, time to freeze, output

Three Key Design Considerations

Footprint

Time to Freeze

Output

How it Works

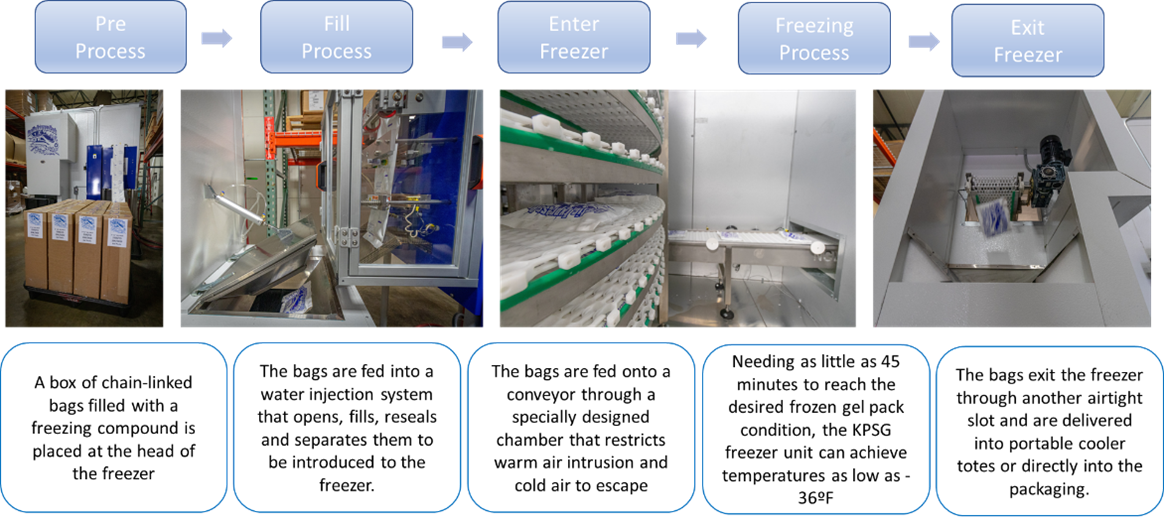

The Arctic Express Pack manufacturing process has been engineered to be completely automated yet can easily accommodate human intervention at the front and back ends of the production process.

BENEFITS

There are several benefits to the system but the ability to get gel packs to a user-specified temperature in a smaller footprint and only use what you need is a game changer. The additional benefit is the reduction in carbon footprint, including:

$100,000 Annual Savings

A cost-analysis comparison between the Artic Express system and a traditional gel pack manufacturer found that a facility that uses 24,000 gel packs a week will save more than $100,000 annually in ancillary costs by converting to the Arctic Express Pack system.

Up to 97% Carbon-Footprint Teduction

As measured in kilograms of CO2 equivalent for transportation, freezer, forklift, and cardboard waste activities, of 96% during the production of 24,000 16-ounce gel packs and 97% for a 24,000-unit pallet of 48-ounce gel packs.