Walk-In Freezers

Products » Walk-In Freezers

Building custom walk-in freezers to spec is what we’re known for.

Walk-in freezers require additional considerations, and with the experience we bring to the table, we are here to help you make sure you get what you need. With each unit custom-built to your specifications, our walk-in freezers set the industry standard. With access to our design and engineering services, your project will be built to your specifications.

Design considerations include the necessary temperature of the box and the needed R-Value which drives the panel thickness. Floor panels or insulated floors are required for all walk-in freezers. Heated vents are necessary for pressure equalization. Heated doors and or sweeps/thresholds are needed. Application considerations like the size of the walk-in freezer may require complicated underfloor venting/heating below the slab to prevent frost heaving.

![]()

Even some walk-in coolers (like Meat or Beer Coolers) should be treated as walk-in freezers due to maintaining temperatures below 32 degrees.

KPS Global does not suggest a wood frame or panels of less than 5” thickness for walk-in freezers. While 4” INSULFRAME (HDR) panels are acceptable per the DOE guidelines as ‘minimum’ R-Value required, this is not always optimal. Based on the Delta-T and humidity conditions, these 4” panels pose a greater risk for condensation issues.

With so many things to consider, call KPS Global to help you with your project. Our sales team will work with our design and engineering teams to build your project to spec.

Whether you need general information or have specific questions, we want to hear from you.

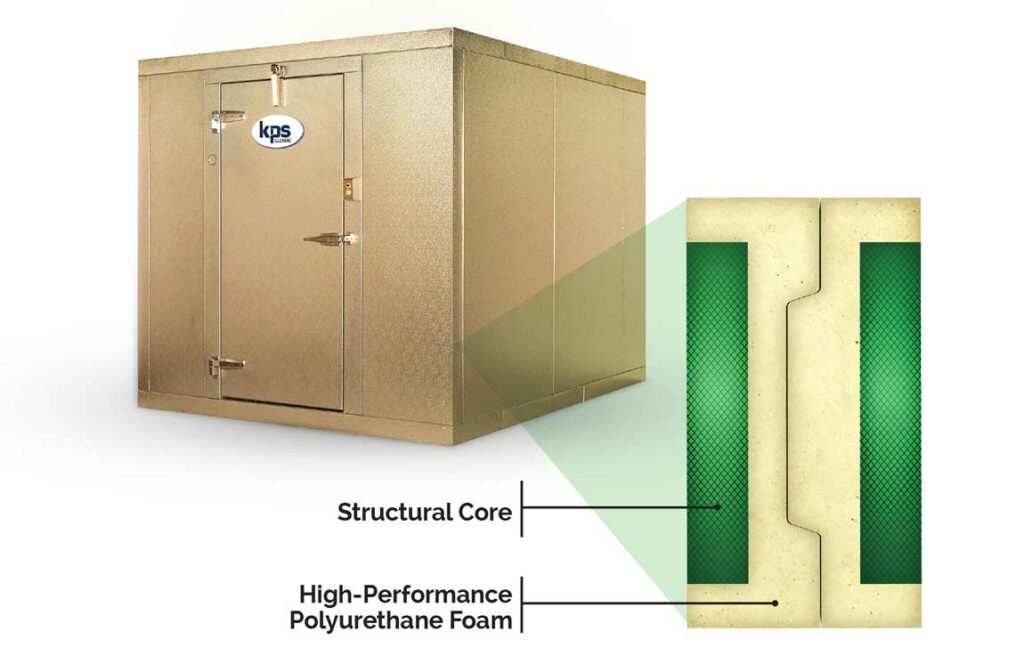

The FUSIONFRAME® system from KPS Global is the ideal solution for walk-in freezers because it truly offers the best of both worlds: the structural benefits of wood combined with the insulative properties of foam. It reduces life cycle performance issues of the traditional wood frames by limiting vapor infiltration, moisture absorption, condensation development and icing of the joint space. It extends the life of a walk-in by reducing the heat that flows through freezers by 50%, drastically enhancing thermal performance and energy savings.

Benefits of FUSIONFRAME®

- The structural core embedded in polyurethane foam insulation allows less heat intrusion than traditional wood-framed rails, resulting in lower cost to operate the walk-in freezer.

- The significantly lower rate of energy flow eliminates the problems that can be caused by humidity and its resultant condensation.

- The FUSIONFRAME® R-value does not degrade over time like wood.

- Reduces the potential for ice to form in the freezer frame like wood.

- The softer foam rail allows for a tighter, more heat-resistant fit at the joints.

- Comparable to traditional wood framed panels in span tests.

- It contributes to a longer operational life cycle for the walk-in cold-storage unit.

- Carbon footprint is reduced through a reduction in the amount of fossil fuels that are needed to create the electricity that is consumed during the operation of the refrigeration system.

KPS Global has your walk-in freezer needs covered. Request a quote today to get started.

Floor panels are constructed in the same manner as the walls and ceilings except for the addition of a substrate under the interior finish. Floor options based on intended use and load requirements:

Foot Traffic: Galvanized or Stainless Steel skins over foam UNIFORM LOAD = 700 PSF

Hand Truck: 1/2” Plywood under any metal UNIFORM LOAD = 1000 PSF

Pallet Jack: 1/2″ Plywood under any metal with ¬field applied 3/16″ DTA UNIFORM LOAD = 2500 PSF

Super Floor: 3/4″ Plywood under any metal with stiffeners at 12″ O.C. and field applied 3/16” DTA UNIFORM LOAD = 5000 PSF

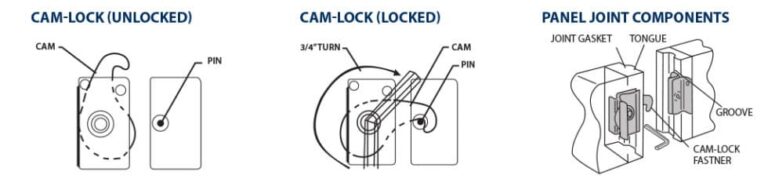

KPS Global panels are modular for ease of assembly with interlocking tongue-and-groove joints. KPSG uses a poured-in-place, HFC-free urethane for superior insulation.

Panels are designed for indoor or outdoor applications. Panel operating temperatures are -40F to 175F. In addition, panels can span up to 22’ without any additional support in most indoor applications.

Tight-sealing, factory-installed double bulb-type NSF approved compression gaskets.