DESIGNED TO REFACE AND INSULATE EXISTING INSULATED PANELS

IMPROVE PANEL APPEARANCE AND INCREASED PERFORMANCE WITH THERMAL LINER PANELS

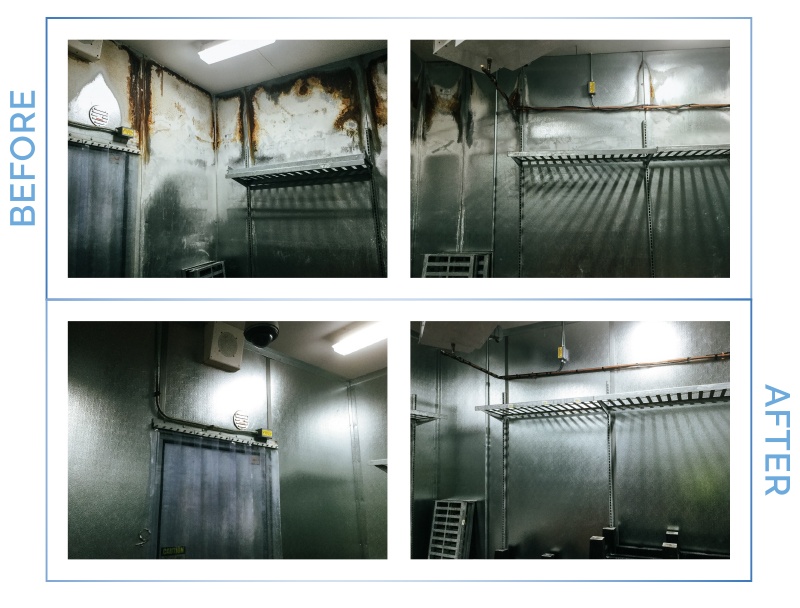

- Restore panel damage from normal wear and tear

- Refurbish corroded, discolored, or stained panel surfaces

- Repair joint displacement due to condensation or icing conditions

GET MORE YEARS OUT OF YOUR EXISTING WALK-IN

- Existing panel life can be increased by up to 5 years

- R-value improvement is achieved by re-facing and insulating existing panels

- Low-profile panels can match existing finishes, providing a fresh appearance

- Meets NSF standards

HOW DO THEY WORK?

- Easy to install liner panels wrap the existing panels

- Constructed of a durable panel face material bonded to an insulated core

- Attached by a proprietary strip assembly system that includes an integral gasket seal (can be NSF Certified)

- Thermal liner panel provides an additional layer of insulation which improves thermal performance

LINER PANEL INTRODUCTION

“Not only did the liner panels give our cooler boxes a fresh new look, they brought them up to spec —ensuring we’re ready for our next inspection — which will save us a lot of money down the line. The best part was the installation was quick and easy – the crew was in and out in no time.”

Shawn Shaffer

Service Purchasing, REMCO, Inc.

Thermal Liner Panel Options

PANEL FACERS

- 26ga Embossed Aluminum-Zinc Alloy Steel.032″ Embossed White

- Aluminum Fiberglass Reinforced Plastic (FRP)

PRODUCTION SIZES

- Panels are all field cut for custom applications and are produced in 47″ widths

THICKNESS

- 0.75″

- 2″

INSULATION IS CLASS A, ASTM E-84 TESTED FOR FLAME SPREAD AND SMOKE DEVELOPED INDEXES, AND UL 1715 TESTED FOR THERMAL BARRIER PERFORMANCE, FOR COMPLIANCE WITH IBC 2603

INSULATION CORE THICKNESS AND R-VALUE AVAILABLE

| Nominal Thickness | Thermal R-Value |

|---|---|

| Inches | °F • ft2 • hr/Btu @ 75°F mean temp. |

| 0.75 | 5.0 |

| 2 | 13.1 |

QUICK AND COST-EFFECTIVE OPTION TO REPLACEMENT

THERMAL LINER PANEL APPLICATIONS

Thermal Liner Panels are a quick and cost-effective option to restore and repair panels without needing replacement. Liner panels provide a great solution to the following issues:

Joint Displacement Due To The Following Issues:

- Condensation

- Icing Conditions

Panel Damage Due To The Following Issues:

- Normal wear and tear

- Discolored, stained or corrosion of panel surfaces

- Impact by carts, lifts, or pallet jacks

- Addressing food safety issues

- Walk-in not keeping temperature

- Not appropriate for cooler to freezer product conversion