The Situation

A refrigeration contractor with over 50 years of experience approached KPS Global seeking a custom insulated panel solution for one of their customers. This customer, a custom food manufacturer aimed to expand their production capabilities by remodeling an existing warehouse into a new food manufacturing facility that required multiple cold storage and temperature controlled solutions.

The Challenge

The refrigeration contractor faced the challenge of transforming a traditional industrial warehouse into a food manufacturing facility while overcoming obstacles such as precast T-shape concrete ceilings, multiple mezzanines, varying ceiling heights, and the need for different climate-controlled areas for the manufacturing process. The project required meticulous planning and execution to ensure the efficient operation of the manufacturing plant.

The Response

Taking a hands on approach, KPSG employees walked the jobsite with the refrigeration contactor to evaluate options. After reviewing the site and understanding the height requirements and limitations the trusses presented, KPSG knew Cam-Lock panels would not work in all areas of the warehouse.

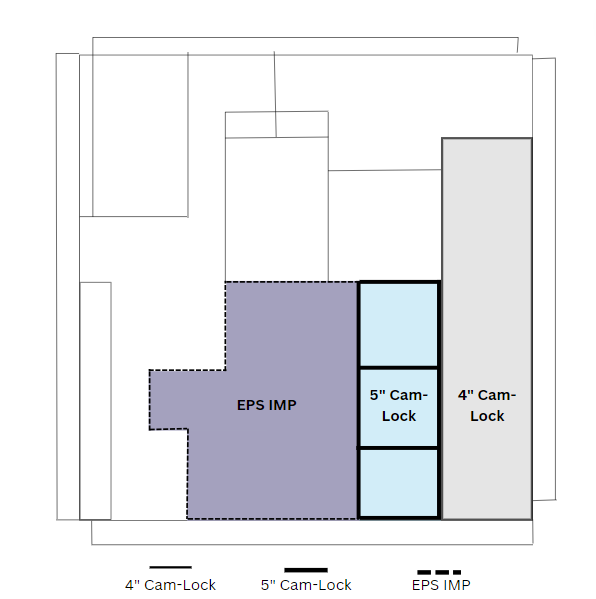

As a result, KPS Global proposed a comprehensive solution to address the project requirements and challenges. The response involved proposing a combination of three custom insulated panel types: 4” Cam-Lock, 5” Cam-Lock, and EPS IMP to create a cost-effective solution that met the needs of the project.

This approach allowed for flexibility in accounting for the many different mezzanines, ceiling heights and the varying climate-controlled areas within the same building providing ease of installation and optimal performance across different areas of the warehouse.

The Solution: Custom Insulated Panels

KPSG delivered a combination of custom insulated panels including 4” Cam-Lock, 5” Cam-Lock, and EPS IMP Panels as the Continuous Line Panels® provided flexibility that Cam-Lock panels couldn’t. Because CLP panels are field cut, they gave KPSG the ability to navigate and work around the fingers of the concrete decking. Because Cam-Lock panels are designed to spec, there were concerns about the team being able to give exact measurements for each column to allow for a seamless installation in certain areas of the warehouse. Therefore each panel was carefully considered based on each specific area of the warehouse. While CLP and Cam-lock panels were chosen, IMP panels were up for discussion but were eliminated as a product consideration due to cost.

Conclusion

Leveraging the broad range of products, KPS Global crafted a custom insulated panel solution for the customer. Thanks to lots of planning early on, KPS Global demonstrated its expertise and ability to transform existing spaces into functional and efficient manufacturing facilities. The project showcased the importance of custom solutions in overcoming complex challenges of project specifications.