Walmart Central America Director of Supply Chain & Manufacturing Strategy and Growth discusses their customerdriven, global supply chain approach

also in this edition

Do you work with a disruptive and innovative company that’s going places?

We want to hear from you.

Tell us all about the startup or SME by emailing enquiries@ithink.media and we’ll consider them for inclusion in an exciting project we have lined up in 2024.

Subscribe and keep your eyes peeled. More to come soon…

FROM THE EDITOR

Welcome to the April 2024 edition of CHAIN Magazine!

Spring is in the air here at the iThink Media head office – the longer, lighter, warmer days are lifting spirits all around. We have a jam-packed line-up this month with six exclusive interviews for you to dive into.

For our cover interview this month, I chat with Francis De Pass, Director of Supply Chain & Manufacturing Strategy and Growth at Walmart Central America about the company’s international supply chain strategy and approach to sustainability. Francis describes how the end goal is to help customers save money and live better, while simultaneously striving for continuous improvement as a business (p6).

Dimitri Fleitman, Head of Supply Chain at Dole Foods of Canada joins me to discuss embedding new technology and sustainability into the company’s global supply chain. We dive into the ‘Farm to Shelf’ supply chain strategy at Dole Foods, exploring the company’s approach to distributing goods and cultivating partnerships along the way (p24).

I speak to senior executives from the SAP Digital Supply Chain organisation in the Middle and Eastern Europe (MEE) region to explore the empowering and energising potential of digital transformation, the cloud and fully automated manufacturing. My conversation with Dr. Johannes Tulusan, Chief GTM & Customer Advisory Officer, Digital Supply Chain (MEE); Ralf Lehmann, Vice President, Global Head of Industry 4.0; and Dominik Metzger, Global Head of Software Engineering – Digital Supply Chain also offers readers a sneak peek of the ground-breaking technology SAP will be showcasing later this month at HANNOVER MESSE 2024 (p38).

I sit down with Simon Bullimore, Head of Group Procurement at Norse Group, the largest Local Authority Trading Company (LATCO) in the UK, about the company’s organisational approach to public sector procurement and striving to improve people’s lives while generating ethical, sustainable profit (p62).

Jeff Monroe, Director of Supply Chain at KPS Global®, North America’s largest manufacturer of walk-in coolers and freezers, tells me all about the company’s recent transformation and growth – driven by supply chain innovation and sustainability strategy (p80).

Jaime Paiva, Head of Procurement and Vendor Management EMEA, and Chris Minter, Sustainable Sourcing Lead of Zurich Insurance Group join me to describe the tech and strategy behind the company’s sustainable approach to procurement. Jaime and Chris offer rich insights into Zurich Insurance Group’s purpose to ‘create a brighter future together’ (p106).

Our features this month cover the global startups transforming concrete production in the construction industry (p70) and wielding technology to predict disruptions and forge a more efficient international supply chain (p94).

We are thrilled to welcome Tiffany MacKinnon, Head of Global Supply Chain Services at HCL Technologies, as the guest in our new recurring feature In the company of… (p128).

We hope you enjoy our latest edition. As always, if you would like to be considered as an interviewee or if you have a story for us to include, please do get in touch.

3

+44 (0) 203 890 1189 enquiries@ithink.media d.harris@ithink.media t.barnes@ithink.media editorial@ithink.media Editor Ben Craske Director Danielle Harris Director Tom Barnes design@ithink.media Senior Digital Designer Daniel May All rights reserved. Every effort is made to ensure the accuracy of material published in CHAIN Magazine. However, the company cannot accept responsibility for the claims made by advertisers or contributors, or inaccurate material supplied by advertisers. CHAIN magazine is a product of iThink Media Ltd. Company Registration Number: 10933897. Company Registered in England and Wales

APRIL 2024

4 APRIL 2024 38 Dr. Johannes Tulusan, Ralf Lehmann and Dominik Metzger from SAP on the future of cloud technologies and fully automated manufacturing 70 Meet the emerging companies leading the way for more sustainable concrete production 80 We speak with Jeff Monroe about the supply chain innovation driving KPS Global’s transformation and growth 94 How can new technologies build a more efficient supply chain? 6 Francis de Pass discusses Walmart’s customer-focused international supply chain strategy 24 Dimitri Fleitman on how Dole Foods of Canada is incorporating social responsibility and new technologies within the supply chain 62 Simon Bullimore explores Norse Group’s organisational approach to procurement in the UK public sector 106 Jaime Paiva and Chris Minter on Zurich Insurance Group’s sustainability aspirations 128 In the company of… Tiffany MacKinnon of HCL Technologies (HCLTech)

5 38 6 24

128 80

Chris Minter

Tiffany MacKinnon

Francis de Pass

94 70 62

Dr. Johannes Tulusan

Simon Bullimore

Dimitri Fleitman

106

Jeff Monroe

COVER STORY

7

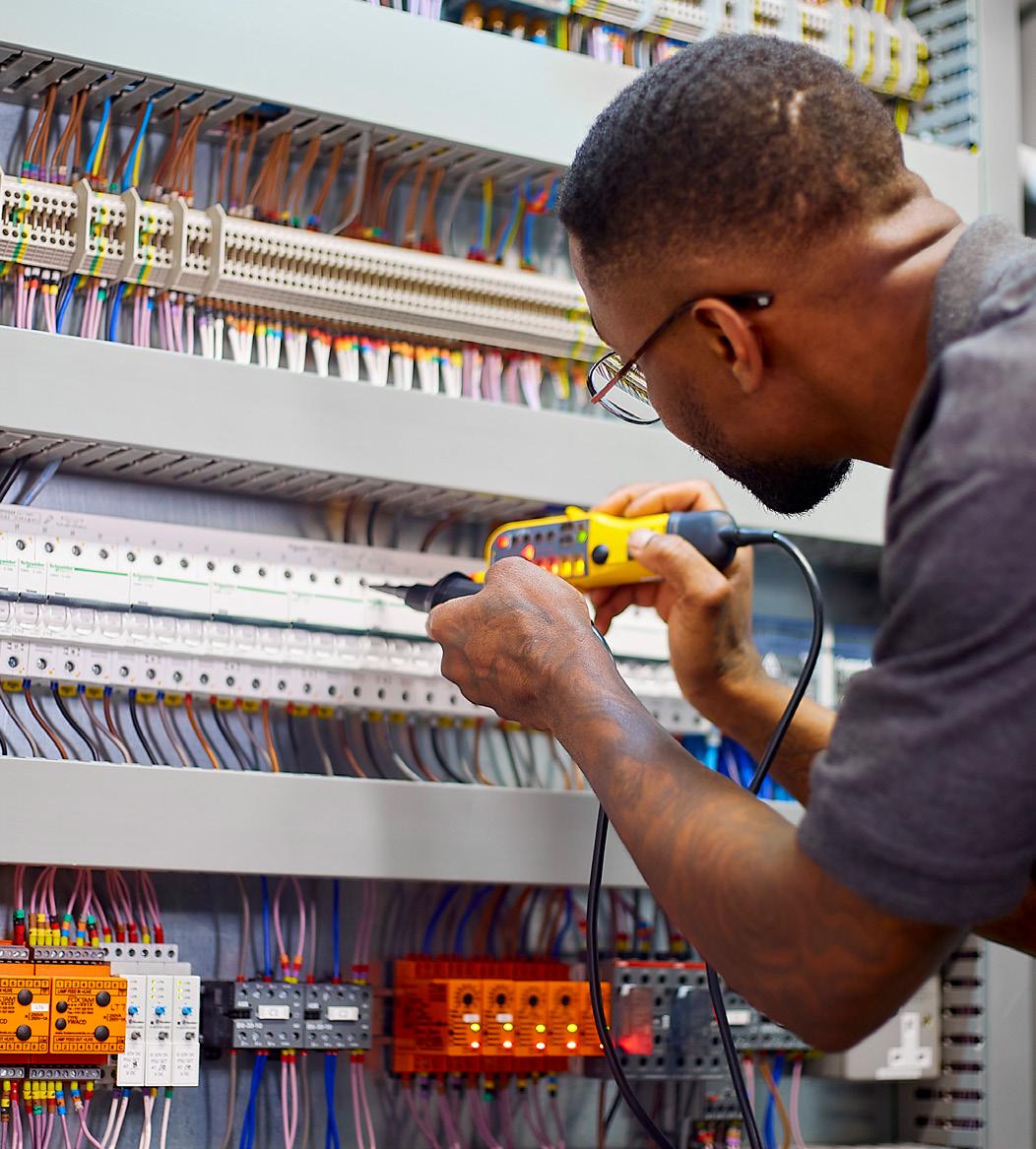

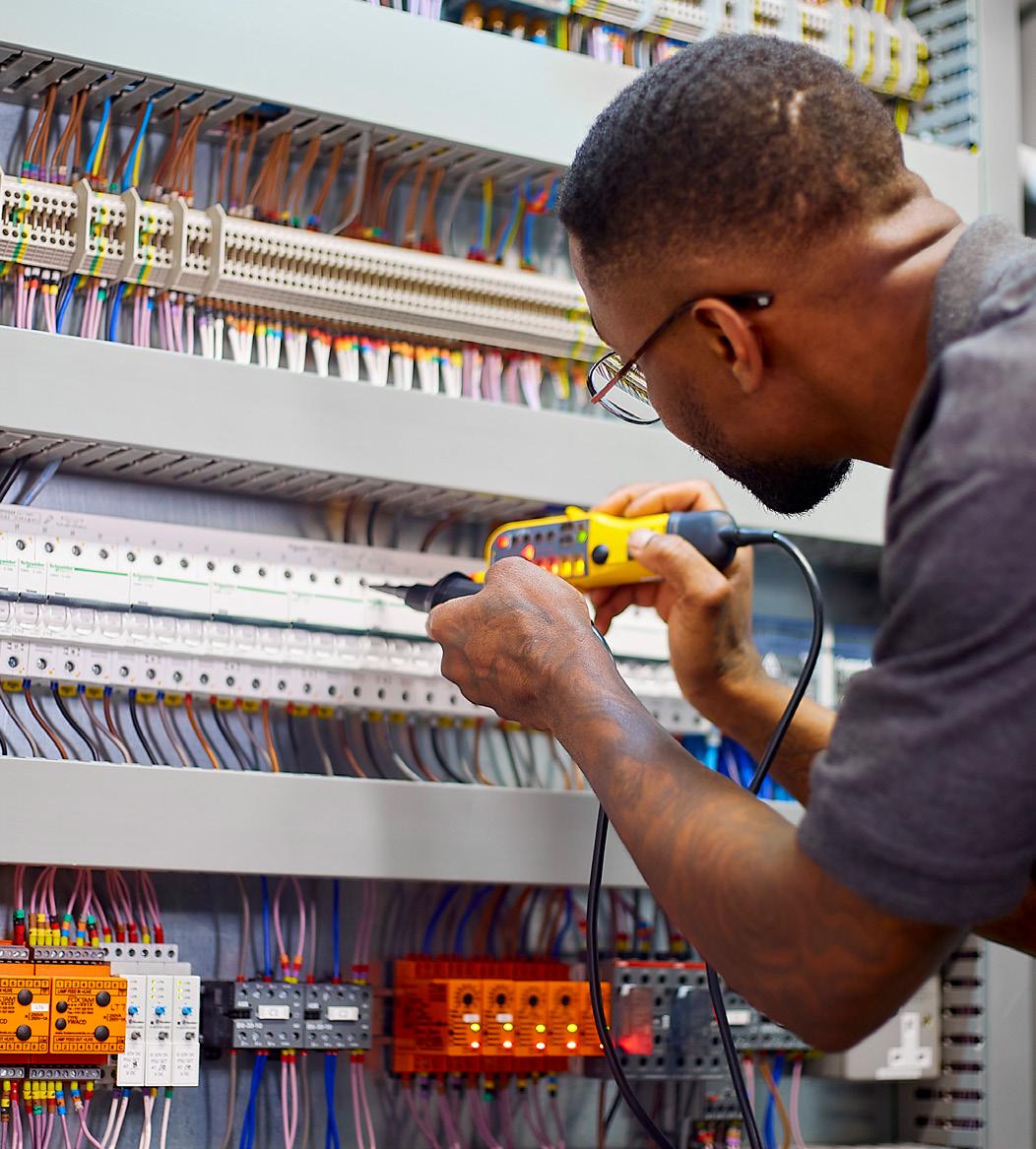

Francis de Pass, Director of Supply Chain & Manufacturing Strategy and Growth of Walmart in Central America on the company’s customer-driven, international supply chain strategy.

Bringing convenience and value to millions of customers in 19 countries outside the US, Walmart International helps people save money and live better lives.

ith more than 5,400 retail units and approximately 550,000 associates around the world, Walmart International’s strategy is to build and empower strong local businesses – while simultaneously generating growth for the company and its partners, positively impacting all stakeholders.

Speaking on behalf of the Central America division of Walmart International, Francis de Pass, Senior Director of Supply Chain & Manufacturing Strategy and Growth, joins us to discuss the company’s approach to supply chain and sustainability strategies, with the end goal of serving customers and striving for continuous improvement.

Francis has been with Walmart for nine years and he has witnessed exponential growth during his time at the company. Francis explains that Walmart’s presence in Central America emerged from an acquisition of a joint group of

retailers, manufacturing facilities and distribution centres in the region, including Costa Rica – where he is based.

“Walmart is a tech-powered, peopleled omni retailer, with close to 900 stores in Central America across five countries: Guatemala, Nicaragua, El Salvador, Honduras and Costa Rica,” says Francis. “We've got four formats of stores – our hypermarket, supermarkets, compact discount hypermarket and discount stores. Since the onset of the COVID-19 pandemic, we have embarked on an omnichannel transformation, expanding our retail presence to include both e-commerce and brickand-mortar stores.

“In Central America, we have inherited a multifaceted retail landscape, and my role entails overseeing the ‘support department’ for our pure operators. These operators encompass distribution centres, manufacturing operators

9

“Walmart is a techpowered, people-led omni retailer, with close to 900 stores in Central America across five countries: Guatemala, Nicaragua, El Salvador, Honduras and Costa Rica”

and transportation,” begins Francis. “I am responsible for leading the support departments, which include Maintenance, Environmental Health and Safety (EHS), Food Safety, Sustainability, Quality Assurance, Systems (including our proprietary warehouse management system (WMS) and SAP platform), Engineering, and Network Planning.

I am proud to work alongside a team of 600 talented associates who contribute to the success of our operations.”

Due to the complexity of the retail environment Walmart inherited when it entered Costa Rica and Central America, Francis describes the need for innovation in its end-toend supply chain strategy.

“To support the stores and the e-commerce part of the business, we have 13 distribution centres and 11 manufacturing plants,”

10

11

says Francis. “The manufacturing plants make high-quality private brand products from meat and packaged grains to bakery goods – you name it, and we make them in-house through our manufacturing division. These products are then sent to the distribution centres before being delivered to our stores – this arrangement forms the core of our supply chain.

“But in conjunction, Walmart has become an important importer of merchandise in Central America since some of the countries we operate have an above-average need for imported goods. In certain merchandise categories, the manufacturing capacity inside the countries is not enough to sustain the needs or the demands of the customers.

“As such our supply chain is incredibly complex: 900 stores divided into four banners, plus our 11 manufacturing plants and 13 distribution centres spread over five countries where, in some cases, bureaucratic and inefficient importing processes on borders prevent supplying from one source. Bringing these dynamics together into a smooth operation would not be possible without an end-to-end supply chain strategy.

“This is where things get really interesting for me and my colleagues in our division. What we do is ensure we are able to sustain and promote

Maxi

the company’s growth every day, every year. Walmart Central America has been growing intensively and still has huge ambitions going forward so we're having more merchandise flowing through our doors, distribution centres and transportation departments year on year.

“To achieve this flow, we need to maintain three things simultaneously, at any time. First, we must be customer-centric: every decision we make has to add value for our

12

Palí is one the banner names for the compact discount

by Walmart Central America customers. Second, we have to operate end to end. Supply chain has a whiplash characteristic to it: anything that you do upstream will flow downstream. Third, we must be data-driven. While there is something to be said for our professional gut instincts, ultimately all final decisions in our strategies must be informed, arising from clear evidence. This is how we make our supply chain an end-to-end value stream, not just a cost stream.”

Elaborating on the first dynamic of

operating in a customer-centric manner, Francis emphasises how Walmart is constantly striving to improve its value proposition for shoppers and that supply chain strategy is intrinsically connected to this endeavour.

“We have various types of customers with different shopping habits,” says Francis. “So when we think about the customer, we tailor targeted customer value propositions based on their demographics and shopping inclinations, taking into consideration how they engage with us in-store or online.

“Our mission at Walmart, set by our founder Sam Walton, is to save people time and money so they can live better. Whenever and wherever people shop with us, we want them to leave with an experience where they feel that they were given something back. This might be that they saved money, had a pleasant experience in-store and/or saved time by shopping with us online.

“We make sure our supply chain is a value-adding aspect of the business by establishing teams that cross the supply chain-storeonline relationship and thinking of our job as facilitating merchandise flow all the way to the hands of the customer: every part of the chain has to contribute in terms of speed, quality and cost. We find the friction points and work on reducing or

13

discount hypermarket operated

eliminating them as much as possible.

“So, based on our customer value propositions (CVPs), we make sure our supply chain strategy is set as a vehicle for delivering value. Any dollar that we add as cost is something that will have to be paid back by the customer, but on the other hand, any dollar saved can be passed onto the customers. Online, any time we can reduce through our supply chain

or operation is time we save for our customers. For me and my team in supply chain, it’s about considering our place in relation to the customer – how do we contribute to make sure they find what they want, when they want it, while saving them time or money to live better?”

Striving towards these goals and incorporating new solutions requires considered strategic planning and internal collaboration, according to Francis.

“When we think about our solutions we have to embrace continuous improvement in the present and boldness for the future”

Masxmenos is one of the banner names for the supermarket format operated by Walmart Central America

“Powering the Future - Everywhere for Everyone.”

At EnerSys, we pursue perfection to deliver Power to innovate and inspire.

Power delivered simply, safely and sustainably.

Power that creates superior value for our customer.

We are proud to be EnerSys.

“When we think about our solutions we have to embrace continuous improvement in the present and boldness for the future,” says Francis. “In terms of the latter when it comes to planning ahead, we have a 10+ year horizon for planning in supply chain and manufacturing for Walmart Central America. Our end goal is to be working on our capabilities 10-12 years into the future, looking at which constraints will arise on storage, throughput, infrastructure, etc and designing the best long-term solution for it.”.

“So, this means that in my department of network planning, when we look at what's planned to happen for the next 10 to 12 years,

QuickPick® Order Picking Technology

Automate low-level order picking to:

● Increase operator productivity

● Promote safety

● Lessen operator fatigue

● Reduce damage to equipment, facility and materials

● Save seconds per pick

Scan today and learn how to revolutionize your order picking

we need to communicate and engage with colleagues in other business units. We have a very close relationship with our real estate department which oversees store growth and with our store operators to design our future supply chain considering the optimal frictionless exchange with stores. We also have a very close relationship with our omnichannel division, looking at what they have planned on that front for the coming years. We ask ourselves and our internal clients, ‘what role should supply chain play for these departments and others across the company?’ We keep our finger on the pulse, share everything, consider all the variables, anticipate developments and work backwards

16

crown.com

to construct the supply chain of the future, today.”

Francis explains how he and his team channel concurrent strategic planning within the 10+ year approach, so they adjust their direction based on the successes or challenges in a given year.

“It's a negotiation, a give-and-take scenario,” summarises Francis. “We set our sights on the 10+ year horizon, but our concurrent planning approach compares last year’s forecasts against the current year’s performance – establishing accuracy levels that yield our decision-making agenda for the future. We believe it is best practice to set a 10-year horizon in supply chain. Going further than this horizon reduces your accuracy significantly, but at the same time it provides enough anticipation to react on time. It gives you opportunities to work with finance to secure the required CapEx and/or OpEx, consult with planning to put smart project timelines in place and ensure bold strategies in the future.

“When it comes to continuous improvement in the present, it’s a little bit different, as the year-onyear dynamics of the retail sector might include inflation, deflation or national holidays – you have to be dynamic and flexible.

of the month when most public or government organisations and private companies tend to pay wages. If those paydays land on a Friday, we know there's going to be a peak weekend, so we adjust accordingly. Striving for continuous improvement in the present certainly keeps us on our toes.”

So how does Walmart uphold quality whilst balancing adaptability and flexibility in the present with a bold vision for the future? Francis highlights five core components:

• 5S Methodology

• Kaizen

• Value Stream Mapping

• Integrating Business Intelligence and AI

• Internship Program

5S Methodology

“For instance, in Central America, we identify in a rolling forecast what we call Pay Days which is the day

“The Five S’s is a methodology developed in Japan, which have been translated to sort, set in order, shine/clean, standardise and sustain,” explains Francis. “We embrace the 5S Methodology to organise a productive work environment every day, executed by micro teams in all departments who look for ways to improve efficiency and effectiveness at a grassroots level. We trained more than 50 of these teams which are starting new projects and making progress in their parts of the business, which is an empowering and rewarding endeavour for those involved.”

17

“Walmart is publicly committed to its sustainability goals. The four major areas we focus on are climate, nature, waste and people. Our goals are based on these regenerative commitment pillars”

Kaizen

“We also have a Kaizen or continuous improvement methodology working culture within supply chain and manufacturing,” says Francis. “Kaizen is another business philosophy from Japan related to perpetual improvement of processes and operations which involves all employees.”

Value Stream Mapping

“Here we integrate engineering philosophy to consider the multitude of processes we wield and map them out to understand where we have non-value-added tasks,” says Francis. “We eliminate or mitigate these as much as possible, meaning that there's no costs or negatives associated with our processes which are not for the good of the merchandise or the good of the company.”

Business Intelligence and AI

“Recently, we started integrating business intelligence into the supply chain by incorporating and streamlining the vast amount of data that we operate with,” says Francis.

“At the moment, the data is spread across hundreds of databases and they’re not very well interlinked. We are making progress on this front because we have launched business intelligence units which have started gathering data, actively pursuing insights and trends we were missing out on before. In conjunction, we are exploring the potential of artificial intelligence. How can we organise our data better? How can we simplify complex tasks? We’re in the early days here, but it’s an exciting journey to be on.”

Internship Program

“We have been working a lot with internships by partnering with several universities in the five countries we have a presence in within the Central America region,” says Francis. “Each semester we welcome students and offer them rich professional insights through the chance to work with us in the supply chain department. We’ve seen some incredible talent step across our doors with fresh eyes and perspectives, many of whom end up working with us after they complete their degrees.”

18

Within the broader sweep of the endto-end supply chain strategy and customer-driven approach at Walmart Central America, Francis adds you cannot separate these endeavours from the sustainability agenda at the company. Here he highlights four main pillars of Walmart’s approach.

“Walmart is publicly committed to its sustainability goals,” begins Francis. “The four major areas we focus on are climate, nature, waste and people. Our goals are based on these regenerative commitment pillars.

“The climate commitment pillar is anything to do with our emissions and energy. Our goal is to have zero emissions by 2040 and powered by 100% renewable energy by 2035.

“For the nature pillar, this is where we've committed to land and sea environmental protection. Walmart

has set its sights on protecting millions of acres of landscape and millions of square miles of ocean. Within this pillar, we also deploy sustainable commodities strategies with key resources like palm oil, paper, pulp and timber, soy and seafood.

“With waste, we are transforming our approach to landfills. We strive to divert all waste from going into landfills by 2025. Here in Central America, we have perishable distribution centres to avoid the wastage of fresh produce.

“Finally, the people pillar entails responsible recruitment practices, fostering a positive working culture, helping the communities where we operate and empowering small businesses.

“Our sustainability agenda is incredibly ambitious and here in

19

Palí is one of the banner names for the discount format operated by Walmart Central America

Central America specifically we have several exciting projects underway. From using solar energy and recycling water at our manufacturing plants to composting at our stores and starting a pilot for a biodigester at one of our perishable distribution centres – we take a proactive and enthusiastic approach to our sustainability responsibilities.”

One of the exciting projects Francis highlights here also reflects the importance of partner collaboration in striving for sustainability. As Francis explains, pharmaceutical distribution poses unique challenges as the products need to be kept at controlled

temperatures and the total volume of the loads tends to be lower.

“We’ve started working with Cori Motors as a trusted dealer of Build Your Dreams (BYD) vehicles to develop a cold chain logistics capacity at the Walmart pharmaceutical distribution centre in Costa Rica,” says Francis. “We have started working with Cori Motors through the BYD brand to deploy the BYD T9, an EV van with robust air conditioning and hauling capacity. Cori Motors and BYD have been great partners helping us reduce our carbon emissions in our journey towards net zero.”

Looking ahead to the future, Francis

BYD IS THE #1 EV BRAND IN COSTA RICA

BYD Costa Rica stands out as the premier EV brand in the nation, leading the charge with more than 6,000 units sold since 2019, with its best-selling model, the BYD S1 PRO, exceeding 3,500 units sold. Complementing this success are models like the BYD YUAN PLUS, BYD TANG, BYD DOLPHIN, BYD SEAL, and the latest addition, the BYD SEAGULL. Moreover, BYD has formed strategic partnerships with multinational corporations such as Walmart, leveraging electrical products to slash carbon footprints and operational costs. Notably, the revolutionary Blade Battery sets the standard for durability, boasting an impressive lifespan of 1,200,000 km. Backed by an 8-year or 150,000 km warranty, this cutting-edge technology ensures reliability and longevity, further cementing BYD’s commitment to sustainability and innovation. As the preferred choice for eco-conscious consumers and corporate partners alike, BYD continues to drive towards a greener, more sustainable future for Costa Rica and beyond.

www.bydautocr.com

“Cori Motors and BYD have been great partners helping us reduce our carbon emissions in our journey towards net zero”

believes there will be several key innovative moments in the next 10 years for Walmart International in Central America.

“We're always designing and constructing the supply chain of the future,” insists Francis. “We have a few big projects in the pipeline. One of them relates to the distribution of ambient and perishable products in two of our key markets, which are multimillion-dollar projects. We’re also very excited about the biodigester pilot at one of our sites here in Central America. It’s a trailblazing project for the company which we hope will transform how we manage our perishable waste.

“We’re also looking forward to starting EV trials with several of our vendors in the next two or three years. Central America is a prime space for trialling EVs because the current range for a trailer is what we will normally do as a back-and-forth journey to any of our stores, even our longest trips. We have consistent weather and varied topography so the vehicles can be tested comprehensively.”

For further information about Walmart, visit corporate.walmart.com.

Turn over for 'ADDED VALUE' with Francis.

21

ADDED VALUE

A rising tide raises all ships

Francis celebrates the professional collaboration and opportunities to share knowledge in the supply chain industry.

“For us supply chain professionals, we have to look at ourselves as peers and not competitors,” says Francis. “We all have similar goals regarding sustainability, productivity and efficiency and we are in prominent positions to influence decisionmaking. We have a huge responsibility and I like to keep up with what my peers are doing.

“I have a few companies I admire what and how they're doing, and I don't see them as competitors, I see them as inspiration. BrewDog and its founder James Watt in the UK are a prime example, as is IKEA or Mercadona. I follow these people and companies because they share insights and solutions, which I like to then explore further and consider in the context of Walmart and my team.

“For instance, I saw a LinkedIn post by James about a project to run a percentage of the BrewDog

vehicle fleet using methane made from by-products of their breweries. Something clicked for me and I took the idea to my team, and from there we forged a business case for our biodigester pilot project in our Perishable Distribution Centre in Costa Rica.

“I like to connect with my peers so we can interact and engage with one another – I’ve found some great ideas from exchanges with my network. LinkedIn is a great opportunity for you to expand your network and start seeing what other people are doing and how they're doing it, as are magazines like CHAIN.

“In a similar vein, a major source of inspiration for me is the World Economic Forum,” says Francis. “I keep track of what they're doing and love how they highlight smaller companies that are developing breakthrough technologies and innovating sustainability strategies like thermal energy storage for cold warehouse and compact wind power to be placed on rooftops which are two ideas we have in the lab right now.”

Connect with Francis

BUSINESS INTERVIEW

Empowering eat

Empowering consumers to eat healthier and live better

25

Dimitri Fleitman, Head of Supply Chain at Dole Foods of Canada on embedding social responsibility and new technology into the supply chain.

With over 120 years of history, Dole Foods of Canada and its affiliated companies have established themselves as global leaders in delivering high-quality packaged fruits, juices and snacks, supplying 75 countries with over 300 products.

riven by consumer desire for wholesome food options that deliver on taste, Dole is on a never-ending pursuit of new innovations across every category, such as snacking, beverages, ingredients and frozen treats. The company has become a world leader in growing, sourcing, distributing, and marketing fruit products and wholesome foods, offering a full line of packaged shelfstable fruit, beverages, frozen goods & novelties, as well as snacks.

Joining us from Dole Foods of Canada is Dimitri Fleitman, Head of Supply Chain, to discuss how the company’s goal to provide a positive impact on “people, planet and prosperity” has led to a more robust global supply chain.

In his role, Dimitri focuses on ensuring the efficiency and effectiveness of the company’s global supply chain operations and its deliverables towards the Canadian Marketplace, through the development of its comprehensive ‘Farm to Shelf’ supply chain strategy, managing the transportation and distribution of goods, cultivating partnerships within the supply chain network, and integrating new technologies.

“At Dole, our organisational approach is deeply rooted in data-driven strategies,” says Dimitri. “We harness the power of cutting-edge technology and data analytics to optimise every facet of our supply chain processes. Specifically, we rely on SAP and Blue Yonder as our primary systems to

26

conduct informed analytics, ensuring heightened visibility, meticulous traceability and data-driven decisionmaking in the realm of supply chain management. This commitment to leveraging sophisticated tools underscores our dedication to efficiency, precision and excellence in navigating the complexities of supply chain operations.

“Through these tailored innovations in marketplace distribution, Dole Foods has positioned itself as a responsive and consumer-focused brand in Canada. The company's commitment to regional adaptation and technological advancements aligns with the evolving preferences of Canadian consumers, setting Dole apart in the competitive Canadian marketplace of packaged fruit products.”

Deploying innovation within the supply chain has been crucial in recent years, with significant global disruptions catalysing the need to develop a more forward-thinking supply chain strategy.

“The last 36 months have been unprecedented in the realm of global supply chain, from dealing with COVID-19, to marketplace volatility due to inflationary economic challenges, followed by global geopolitical events,” says Dimitri. “Issues with supply resilience have notably been amplified, such as disruptions, delays, shortages or volatility with consumer demand

in general have highlighted vulnerabilities. To address these challenges and improve supply resilience, Dole has adopted endto-end supply chain optimisation as a strategic goal for the Canadian marketplace. A sound focus on supply chain resilience ensures elements like fines, demurrage and detention are mitigated, combatting inflationary contributors.”

There are a few key strategies Dole Foods has used to re-engineer its supply chain and amplify its resilience:

Risk Mitigation

“Experiencing disruptions in the supply chain makes companies more aware of potential risks,” says Dimitri. “By optimising our entire supply

28

chain, from the very sourcing of raw materials, followed by competitive sourcing initiatives, re-evaluating safety stocks through statistical forecasting, driving data decision making through the very culture of our operational values, and finally ensuring our partnership selections for Ocean Freight, Warehousing, and Transportation functional pillars are not just a commercial relationship, but really an integrated enterprise where we are extensions of each other’s organisations, allows for vested interests and mutual goals to be achieved.”

Visibility and Transparency:

“Supply chain optimisation often involves enhancing visibility and transparency across the entire supply chain,” says Dimitri. “Dole

has embarked through digitisation tools to ensure our teams have live streams of data visibility to anticipate potential disruptions, monitor supplier performance and make informed decisions to maintain a seamless flow of goods. Key examples of this include live Ocean Freight tracking of our ocean freight shipments, integrated warehousing inventory systems coupled within our ERP and production to shipment confirmations. Our supply chain motto is “inspecting what we expect” – only then can we achieve the level of serviceability and resilience that our customers expect.”

Efficiency Gains

“Global challenges have highlighted inadequacies in the supply chain,” insists Dimitri. “By optimising Dole’s end-to-end processes through routing optimisation, diverting ocean freight to less congested ports and positioning our warehousing and distribution closer to our customers, we have aided in reducing lead times, and minimising waste, ultimately enhancing the overall performance of the supply chain, and hitting the key performance expectations of our customers.”

Collaboration and Communication

“End-to-end supply chain

optimisation often requires improved collaboration and communication with suppliers, distributors, and other partners,” explains Dimitri. “Learning from past issues Dole

29

regularly forums with our partners to build stronger relationships through enhanced collaboration and information sharing. By choosing the right partnerships and embracing transparency in our collaborative efforts, we ensure that systems, services and deliverables are inspected to the level we expect. Dole has always been in an endless pursuit of improvement of our supply chain.”

Technology Adoption:

“Dole, being a data-driven organisation, invests in advanced technologies, such as data analytics,” says Dimitri. “We rely on partnerships for statistical forecasting and supply planning through our Blue

Yonder system, where we automate processes, as well as implement a comprehensive freight planning and routing engineering that has optimised resilience within our supply chain. This technological integration helps Dole Supply Chain in Canada make real-time decisions, aid in forecasting demand more accurately, and improve overall supply chain agility.”

Dimitri also places significant value on company culture in the development of Dole’s highperforming supply chain. “I aim to foster a collaborative and innovative culture, providing direction to the Dole team members to achieve

30

“We rely on partnerships for statistical forecasting and supply planning through our Blue Yonder system”

organisational goals,” says Dimitri. “We thrive on being a team, hence why I would like to call out our exceptional customer service department which is being led by my associate director of customer service in Canada Nathalie Cote, and our operations department associate Director of Supply Chain Carlos Castro.”

For a company as geographically expansive as Dole Foods, having

an effective supply chain strategy is crucial. The consolidated business is among the world’s largest producers of fruit products, with operations spanning globally.

“Dole's intricate supply chain for packaged food products encompasses a global network, with its farms in diverse locations like the Philippines, Thailand and Sierra Leone,” says Dimitri. “A crucial aspect of Dole’s supply chain is ocean freight

31

The Moment Is Now

Blue Yonder is creating the supply chain operating system for the world, including 3,000+ global, innovative and category-defining brands.

Find out how

32

33 Now system 3,000+

“In response to the growing emphasis on better practices in Canada, Dole Foods has taken a leadership role by identifying opportunities to move towards ecofriendly packaging materials”

to ensure our goods are delivered from a farm to table approach. Dole ships tens of thousands of containers globally. Our manufacturing landscape requires our packaged foods transported across continents to regional marketplaces and their respective distribution centres.

“The use of ocean freight enables Dole to efficiently move large volumes of products while navigating international logistical challenges from labour disruptions, geopolitical issues to domestic port challenges. Prior to marketplace distribution, Dole is a data-driven organisation, so we employ sophisticated supply planning systems such as Blue Yonder to plan our worldwide supply requirements.

“Upon arrival at distribution centres in Canada, Dole engineered marketplace propriety ‘hub and spoke’ warehousing operations to manage our goods into inland distribution. Finally, Dole ensures timely and reliable transportation

to customers by leveraging a comprehensive logistics strategy, which includes partnerships with an array of LTL and FTL multimodal transportation providers and distributors. This end-toend approach, encompassing ocean freight, supply planning, warehousing, and transportation, allows Dole to deliver quality packaged goods to consumers worldwide while addressing the complexities inherent in the global supply chain.”

Dimitri expands on Dole’s ‘hub and spoke’ model, and advanced logistics infrastructure the company wields to help navigate the vast and diverse

34

Canadian geography. In this model, the centralised hubs – in this case, the company’s distribution centres – are positioned in such a way that allows Dole to optimise the last-mile delivery process and ensure products are not double-handled. But there are many other ways Dole Foods is embracing innovation, according to Dimitri.

“Dole Foods has embarked on a transformative journey to revolutionise its marketplace distribution in Canada, recognising the unique challenges and opportunities within this market,” says Dimitri. “Leveraging cuttingedge technologies, Dole has implemented a predictive analytics

system designed to account for Canadian-specific consumer preferences, seasonal variations and regional demand patterns. This ensures that distribution sites across the country are stocked with the right mix of products tailored to the Canadian market.

“The company has embraced a localisation strategy, partnering with Canadian e-commerce platforms and retail chains to enhance its presence in the market. By collaborating with local distributors, Dole can ensure that its products are readily available to consumers across provinces, adapting to regional preferences and ensuring efficient

35

distribution within the Canadian marketplace across a diverse set of sales channels.

“Through rigorous process controls, we have meticulously engineered our supply chain to contribute to fewer products facing unnecessary destruction due to demand fluctuations. Given the perishable nature of our products, Dole has strategically forged ecosystem partnerships with local food banks in Toronto and Vancouver. This innovative approach creates a dynamic push system that channels excess supply directly to those in need.

“Our supply chain systems have been intricately redesigned so that when our inventory reaches a designated date code, it is seamlessly coordinated for distribution to food banks. As the steward of this impactful initiative, I firmly advocate for the wider adoption of such practices by corporations.

“Beyond the undeniable social benefits of aiding those in need and feeding the vulnerable, this approach contributes to the reduction of waste and destruction.”

Learn more about Dole Foods of Canada by visiting dolesunshine.com.

Added Value

Partnership Knowledge Network

Dimitri makes networking with partners a priority to stay informed on industry news.

“Establishing and maintaining information transparency with suppliers and service providers is not just a priority but a cornerstone of my approach,” says Dimitri. “Ocean freight carriers, warehousing service providers, and transportation vendors often maintain in-house updates and publications that offer valuable insights. Going beyond conventional communication channels, I actively engage in networking with our existing partners and make it a point to subscribe to their publications. This proactive approach ensures that our team stays well-informed, leveraging the collective intelligence of our network to anticipate market trends, navigate challenges and foster collaborative problemsolving. By actively participating in this information exchange, we not only strengthen our partnerships but also enhance our strategic decision-making capabilities within the dynamic landscape of supply chain management.”

36

Looking ahead

Dimitri is looking forward to the Gartner Supply Chain Symposium / XPO in June 2024, where he is excited to learn about new digitisation tools and connect with vendors.

“Moreover, through my educational background holding an MBA from the Richard Ivey School of Business, having CCLP designation, and the CSCMP designation, I am looking forward to participating in industry community-based events, networking with peers and partners in the supply chain space,” says Dimitri.

Connect with Dimitri

BUSINESS INTERVIEW

Accelerating our success together by unleashing the power of automated manufacturing with business AI

We welcome senior executives from the SAP Digital Supply Chain organisation in the Middle and Eastern Europe (MEE) region to dive into the empowering and energising potential of digital transformation, the cloud and fully automated manufacturing. Read on for a sneak peek of SAP’s showcase at HANNOVER MESSE 2024, along with the latest and greatest insights into how SAP is the provider and partner to help businesses.

39

With

24,000 partner companies

around

the world, SAP customers generate 87% of total global commerce. SAP’s goal is to be the number one enterprise application and business artificial intelligence (business AI) company, powered by its leading platform and 107,000 employees in 156 countries.

oining us today are key members of the SAP team supporting this effort: Dr. Johannes Tulusan, Chief GTM & Customer Advisory Officer, Digital Supply Chain (MEE); Ralf Lehmann, Vice President, Global Head of Industry 4.0; and Dominik Metzger, Global Head of Software Engineering –Digital Supply Chain.

Launching our conversation, we’ll be exploring the key trends and opportunities for digital supply chain actors in 2024. Then we learn more about the potential of SAP’s public and private cloud ERP solutions, the importance of moving towards fully automated digitalised manufacturing and the power of

40

“To bring out the best for our customers, manufacturing and supply chains must be more agile, more collaborative and more integrated”

Dr Johannes Tulusan

41

business AI. Our guests will hint at the groundbreaking technology SAP will be showcasing at the HANNOVER MESSE later in April 2024, before wrapping up our conversation by looking ahead to the future of SAP’s digital supply chain strategy.

State of Play

As we enter 2024, digital supply chain professionals are still grappling with the demands of post-COVID resiliency and must come to terms with digital transformation to thrive. Resilient supply chain management to address unforeseen events remains imperative and technologies like artificial intelligence (AI), blockchain, data analytics and the Internet of

Things (IoT) are here to stay as key tools toward that end. Sustainability is the ever-present elephant in the room and businesses envision the need for end-to-end transparency throughout the whole supply chain. These discussions are fundamental, but they are not entirely new. So what is the current state of affairs now we’ve flipped the calendar from 2023 to 2024? And how is SAP adapting to ongoing changes to empower its customers –helping them expand, digitalise and scale their businesses?

“In 2024, there are four major areas in the supply chain which have entered the horizon or evolved for companies in many industries,” begins Johannes. “First, there’s a need for increased automation and agility in supply chain processes. Labour shortages in highly skilled roles plague many businesses, for example in the manufacturing industry. Experts who have been working at companies for many years are starting to retire. The resulting knowledge gap can be closed by increasing the role of automation. Here, SAP can help customers automate and integrate the production, logistics and maintenance areas of their operations.”

Weighing in, Ralf emphasises that promoting automation does not mean

42

“One of the goals for enterprises is leveraging and conserving the skills of experts while building institutional knowledge, but simultaneously bringing younger workers up to speed quickly so they can operate proficiently at a high level in less time”

Ralf Lehmann, Vice President, Global Head of Industry 4.0

removing humans from processes or jobs. Instead, it is about optimising the effectiveness and efficiency of people working alongside machines, together. Moreover, he insists automation can help employees refocus on the more complex tasks that require human ingenuity.

“One of the goals for enterprises is leveraging and conserving the skills of experts while building institutional knowledge, but simultaneously bringing younger workers up to speed quickly so they can operate proficiently at a high level in less time,” says Ralf. “Automation is a highly valuable resource in this pursuit. In recent years, agility in the supply chain has become even more important for our customers. They typically have a dynamic mix of products they're assembling on multiple lines. Businesses need to look from an enterprise performance perspective to identify an efficient production strategy and embrace agile working practices.”

“The second important topic for 2024 is visibility and

transparency within and across the company,” notes Johannes. “Endto-end processes from enterprise resource planning (ERP) to supply chain are a key requirement for digital business. Equally critical is the ability to interact with trading partners in a business network and share relevant data – and this is fast becoming a reality.”

“Third – and this has been an important topic in recent years – is striving for sustainability,” adds Johannes. “Many stakeholders discuss this topic at length, but implementing it is becoming increasingly urgent, in light of the increasing number of new

43

policies and regulations regarding the issue. We are at the stage of moving away from hopeful thinking to making sustainability a reality for every business, but there is still more work to be done –an endeavour which SAP is committed to supporting its customers in.”

“The final hot topic on everyone’s lips is AI, and in particular generative AI,” continues Johannes. “Specifically at SAP, we are enriching all our applications with business AI capabilities to help our customers autonomously enhance their business processes or to optimise business outcomes.”

Transformation Trio: Cloud, Automation and AI

In light of these emerging and evolving trends, what technologies, software solutions, and strategies do Johannes, Dominik and Ralf believe are fundamental for enabling supply chain resilience in 2024? They all agree that it starts with cloud-based solutions, gravitates around fully digitalised, automated manufacturing and weaves in business AI.

Cloud

Elaborating on the importance of the cloud, Johannes stresses that innovation in the cloud is easier than the alternatives and that staying with onpremise systems holds companies back.

“The RISE with SAP offering and the GROW with SAP offering help our customers who have on-premise ERP move into the cloud,” begins Johannes. “Maintaining an ERP system in its own

local data centre becomes quite cumbersome and deploying new innovations like artificial intelligence is only possible in the cloud environment. In 2023, there was a breakthrough in the MEE region where many customers decided to bring their entire business software landscape into the cloud.”

So what is the difference between RISE with SAP and GROW with SAP?

“RISE with SAP is essentially for our customers with existing SAP ERP software landscapes and who want to keep most of their customisations but merge and transform into the cloud,” says Johannes. “GROW with SAP is our ERP solution to encourage customers in what we call ‘greenfield’ approach, where customers want to start afresh, to move all processing into SAP S/4HANA Cloud, public edition. Customers also apply hybrid approaches with RISE with SAP and GROW with SAP, transitioning to the cloud with their existing ERP landscape while at the same time implementing SAP S/4HANA Cloud, public edition for new sites.”

“In relevant industries, digital supply chain professionals have a strong stake in the RISE with SAP and GROW with SAP transformations, since certain key functions they oversee, such as manufacturing, production planning, logistics and product lifecycle management are already embedded within the ERP software solutions from SAP. A resilient supply chain has become a keystone function of any

46

“The first purpose of AI is to empower business users to handle disruptions by delivering all the critical information for rapid decision right to their fingertips”

Dominik Metzger, Global Head of Software Engineering – Digital Supply Chain

business, since it goes hand in hand with growth and transformation.

“Within the next month, SAP plans to announce the offering of supply-chain-specific RISE with SAP packages for our customers, to help them identify the most suitable supply chain solutions alongside their cloud ERP transformation.”

Fully Automated, Digitalised Modular Manufacturing

Ralf adds the agility and scalability of RISE with and GROW with SAP make them ideal solutions for new innovations, particularly in production.

“Clearly supply chain cloud solutions have become much more important in recent years in our MEE region,” reaffirms Johannes. “Before, for instance, we saw digitalisation and production as separate silos, but now we see an amazing trend toward adoption of the scalability of cloud in the digital supply chain and the manufacturing area in tandem, breaking down the silos. The power of cloud solutions lies in their agility in this rapidly evolving context.”

Ralf goes even one further step ahead, by highlighting the importance of fully automated and digitalised modular manufacturing as the future

47

of production. As the technologies facilitating production evolve around end-to-end integration – including cloud ERP, digital manufacturing solutions, automated guided vehicles (AGVs), traceability software, AI and business AI – businesses must lean into the trends, driving and bolstering the global economy, adds Ralf.

AI

Johannes recalls how since 2013, when big data became part of his role at SAP, there has been a developmental journey towards AI as we know it today. Back then, it started with handling vast quantities of master data, turned towards looking at prescriptive data then predictive maintenance before arriving at machine learning and emulating data today.

“Now the focus is moving beyond using data analysis to generate predictions to realise the potential of generative AI and business AI, by training algorithms so we can ask for recommendations, not just summaries or forecasts, while also steering the technology towards learning and improving itself,” explains Johannes. “At SAP, we are developing our business AI to apply artificial intelligence in a business industry context. We realise AI is more than just validation or algorithm analysis, it’s about facilitating learning within the system itself and generating insights and suggestions we might never have come up with ourselves. This is incredibly important in all solution areas, not just digital supply chain.”

Dominik insists that for today’s businesses, AI has two main purposes.

“The first purpose of AI is to empower business users to handle disruptions by delivering all the critical information for rapid decision right to their fingertips,” says Dominik. “The second, and let’s consider this a long-term purpose, is to transform supply chains to become near autonomous and selflearning. Near autonomy, as with self-driving cars, means that a vast majority of essential decision-making is automated, and only the most critical disruptions are managed by expert business users. Automation clearly facilitates supply chain optimisation.

“Optimisation is not a new concept in the supply chain arena, and many companies have already optimised supply planning in several ways. They use forecasting for demand planning and machine learning algorithms for predicting demand for spare parts. Machine learning algorithms help with planning transportation routes and choosing suppliers.

“But what is really tough for many companies is to build trust in the system. If a worker has done their job for 20 years on a manual spreadsheet, why should they trust this new digitalised system? And that's really a sweet spot for generative AI. One example is our generative AI assistant Joule, which revolutionises how we interact with SAP business systems, making every touchpoint with the system simpler by just asking to get

48

tailored results for a business process step. As an end user, once I’m included in the discussion, I have much more faith in my optimised system and its output supported by generative AI capabilities.

“The role that generative AI can play then is to lower these adoption hurdles for users of optimisation and advanced forecasting,” summarises Dominik. “When we look at logistics, we can specifically talk about automation. What’s in the logistics space today can still be a very manual process. For example, in many warehouses and shipping yards of this world, whenever a truck or a container rolls up, someone still needs to check that the paperwork matches the contents, by comparing paper documents in their hand to a screen display. Using generative AI to automate these processes can actually be a game changer.”

Taken together, cloud, automation and AI technologies will revolutionise the future of the digital supply chain – which is why they form crucial components of SAP’s exciting showcase for HANNOVER MESSE 2024.

Hannover Messe 2024

There’s a tangible buzz in the air as we turn our conversation towards the HANNOVER MESSE 2024.

HANNOVER MESSE is the world’s leading industrial trade fair, showcasing cross-industry solutions and interface technologies for the

entire business ecosystem. The aim is to energise sustainable global industry. More than 4,000 companies will be acting as an interconnected industrial ecosystem and attendees from all industries, looking for trusted partners to help them become more resilient and sustainable, are warmly invited to explore SAP’s leading supply chain solutions.

But what can HANNOVER MESSE attendees expect from SAP at the event?

Setting the scene, Johannes shares the theme for SAP’s presence at HANNOVER MESSE: ‘Bring out new manufacturing excellence’.

“Manufacturing is one of the growth engines of the global economy,” begins Johannes. “Successful, innovative manufacturing has a ripple effect across the economy by stimulating growth in related industries.

“Industry 4.0 is about integrating digital and physical worlds, changing the way manufacturers operate, collaborate and engage with customers. Adapting to Industry 4.0 requires a new kind of intelligence –with data at its core – that uncovers new insights, automates operations and optimises decisions.

“To bring out the best for our customers, manufacturing and supply chains must be more agile, more collaborative and more integrated.

50

Business processes need to be as smart as the products we’re making and the customers we’re selling to.”

Ralf weighs in and adds that today’s manufacturing leaders need to know how to combine data from machines, processes and the full ecosystem to make better, more holistic decisions, adapt to changing market demands and harness new technologies – such as generative AI and machine learning – to design, manufacture, deliver, operate and maintain products more efficiently and sustainably.

Offering a sneak preview of SAP’s showcase on modular manufacturing at HANNOVER MESSE 2024, Ralf describes the company’s demonstration of worker and shop floor orchestration including on-hand AGVs from multiple vendors.

“When we go to HANNOVER MESSE, our approach is unique compared to

other events,” says Ralf. “Our goal is to enable attendees to understand the power of the SAP solutions at a deep level, in a tangible, real-world context. How exactly can SAP solutions help them drive better business results? To answer that question, we showcase a vast range of customer examples and demonstrate in person and in real time how those elements interact with real assets.”

Without spoiling any surprises for the big event, we can say that the SAP showcases at the big event in Hannover covers the manufacturing end-to-end process comprehensively: from designing a product and planning projects, to building, delivering, operating and maintaining them.

But fortunately for us, there is one main SAP showcase around automated and modular manufacturing at HANNOVER MESSE

51

1

Discover two powerful assets to accelerate your digital transformation

Transforming business processes through immersive experiences

In the ever-evolving landscape of industry supply chains, BearingPoint takes a bold step forward with its Virtual Reality Platform, revolutionising the way business processes are implemented. The uniqueness of BearingPoint’s approach lies in its ability to provide clients with a better understanding of new workflows and IT systems through immersive experiences. By turning

2

Leveraging the Equipment-as-a-Service demands with Lease & Rent to obtain new revenue stream

BearingPoint’s Lease & Rent solution is an answer to today’s dynamic business landscape, where the global equipment leasing and rental industry faces a paradigm shift. Increasing demands for new business models, flexibility, sustainability, financial risk management, cost efficiency, technological innovations, maintenance and evolving regulations require adaptation. Businesses in this sector,

complex processes into tangible, virtual encounters, the platform plays a pivotal role in fostering a more profound willingness to embrace change within project and business operations teams. This, in turn, becomes a critical success factor in driving larger corporate transformations.

Our platform offers a distinct advantage in the SAP® partner ecosystem. Unlike any other provider, we seamlessly integrate a solution that combines virtual reality expertise with indepth knowledge of SAP® solutions.

including construction, OEMs, and equipment dealers, are transitioning to models like Equipment-as-a-Service. Inspired by the automotive sector, they explore new avenues, being challenging for both startups and established companies.

BearingPoint leads this digital transformation with a revolutionary SAP cloud solution. Lease & Rent modernises management to accommodate new business models, going beyond traditional software by integrating end-to-end leasing and rental processes, covering all the relevant aspects – from request, quotation, invoicing and

By engaging users in immersive experiences, we aim to translate the abstract benefits of SAP® solutions into tangible and experiential encounters, fostering innovative approaches for SAP® sales and transformative SAP® S/4 HANA projects.

Let’s delve into the possibilities together.

throughout the contract lifecycle to maintenance, logistics, and even refinancing.

By harnessing SAP technology, we empower organisations to embrace new models, streamline operations, and stay ahead in an era of constant change and innovation.

Scan the QR code to discover how Lease & Rent can streamline your Leasing and Rental operations:

www.bearingpoint.com

2024 that Johannes, Ralf and Dominik can offer early insights into for our conversation. With all the buzz around fully digitalised modular manufacturing and the role of automation within it, we would be remiss to overlook a full discussion of automated guided vehicles (AGVs).

As it stands in global industry today, AGVs from different manufacturers must run on separate systems in manufacturing and production operations. However, there is growing awareness of the need for interconnectivity and interoperability to support a unified approach to advanced planning, data sharing, visibility and ERP enhancement. And

this is precisely where SAP is going to transform how its customers and partners conceptualise and execute manufacturing and production, with full automation and digitalisation – driven by data, to bring out new manufacturing excellence.

“AGVs perform a crucial support role in logistics, the supply chain and manufacturing operations – to name just a few use cases,” says Ralf. “But the situation today is that each type of AGV needs its own driving arena. Imagine if every type of car needed its own road to drive in – it would be chaos, right? But to bring the metaphor back to AGVs, we are exploring how to

“At HANNOVER MESSE 2024, attendees will see what we’ve achieved: AGVs from three distinct vendors – MiR, Omron and symovo – work simultaneously and safely, in the smallest driving area we could force them into, to prove the concept”

53

create a new environment where AGVs from all manufacturers can operate interconnectedly in the same environment, without needing separate systems to run them.

“Large companies with multiple production slides and several AGVs in their manufacturing processes need to set up intralogistics from one flow. At the moment, joint orchestration is not possible and we want to change this situation.”

“The first step is to be able to orchestrate the AGVs jointly,” continues Ralf. “The second step – and this is where the true innovation potential lies – is to apply business context to the AGVs and share data seamlessly, throughout the entire manufacturing process, to fully automate the production line. The appetite among our customers for such a revolutionary AGV system is staggering, so we have worked with our partner KINEXON to meet this pressing business need.

“At HANNOVER MESSE 2024, attendees will see what we’ve achieved: AGVs from three distinct vendors – MiR, Omron and symovo – work simultaneously and safely, in the smallest driving area we could force them into, to prove the concept. We co-innovated with KINEXON and the AGV manufacturers to develop hardware-independent fleet management system, running multiple devices orchestrated through a KINEXON solution and integrated with the SAP Digital Manufacturing solution.”

Ralf explains the system: “All the AGVs are controlled from a central layer that can talk to each of the devices within the fleet management system. This capability goes well beyond the requirements of the 5050 standard from the German Automotive Industry Association (VDA from its initials in German), the current industry benchmark for AGV communication.”

In fact, SAP solutions harmonise all the technologies that will be

54

© www.joanna.nottebrock.de

proaxia Seamless Service.

With our seamless service approach, you can increase your service efficiency and customer satisfaction!

We are designing and implementing processes & solutions that lay the foundation for a consistent and efficient service experience across all service channels.

Boost your customer engagement through integrated digital self-services!

With our packaged Customer Self-Service (CSS) solution you can create a state-of-theart B2B service portal that supports your business processes with innovative digital selfservices, fully integrated into your processes and SAP landscape.

Our Customer Self-Service enables real-time communication between you, as a manufacturing company (OEM), and your customers.

The digital involvement of your B2B-customer enables direct service relations and strengthens customer loyalty.

Accelerated service processes save valuable time and increase productivity.

Get more information:

www.proaxia-group.com

info@proaxia-group.com

Higher transparency through shared processes and information helps innovate business models and establish new revenue streams. For

55

SAP Industry Cloud

demonstrated at the company’s modular manufacturing showcase at HANNOVER MESSE 2024.

“SAP S/4HANA Cloud is the core digital backbone for discrete manufacturing, and we are demonstrating how SAP Digital Manufacturing integrates with SAP S/4HANA Cloud, public edition running the modular manufacturing showcase,” continues Ralf. “We cannot wait to show attendees this revolutionary seamless integration applying open industry standards and orchestration by KINEXON to enable multivendor AGVs to drive in shared spaces.

“On top of this, we will show attendees how generative business AI and

advanced machine learning will reshape supply chain execution in the way products are designed, planned, manufactured, delivered and maintained. SAP provides the next generation of business applications infused with business AI and empowers manufacturing leaders to leverage unique data assets from manufacturing execution systems, marrying large-scale machine data and ERP data with data from the wider industrial ecosystem to push manufacturing efficiency to the next level.

“We live in a disruptive world these days,” Ralf summarises, “and for most companies, the question is how to best handle and optimise all their flows, infusing every business application and

‘Digital Core For Enterprise Supply Chain’ - Powered By Capgemini

Supply chains have always been complex, and the last few years have taught us how fragile these can be. At Capgemini, we focus on collaborating with our clients to identify and enhance critical elements unique to each customer and their supply chain by leveraging our expertise in processes and technology. We partner with SAP to integrate cutting-edge technology solutions like AI, ML, IoT, blockchain and advanced analytics to enhance supply chain offerings. Our focus areas include Sustainable Supply Chain Strategy, Smart Forecasting, Procurement, Order Orchestration and Reverse Supply Chain Management. Through collaboration with SAP, we drive innovation in supply chain resilience and optimise end-to-end performance management. Our approach integrates these technologies seamlessly, ensuring efficient and agile supply chain operations for clients.

“Intelligent supply chain prioritises resilience, performance and sustainability – enhancing augmented customer-centricity.”

As a partner in Business Technology and Digital Services Transformation for Supply Chain Management (SCM), we drive business outcomes:

• Up to 15% reduction in inventory costs

• Up to 20% improvement in demand forecasting accuracy

• Reduction of overall transportation costs by 10% - 15%

To know more, please visit - www.capgemini.com

56

process with the latest technologies for digitalisation, data management and artificial intelligence – transforming the end-to-end value stream with SAP’s support.”

Connect with SAP’s experts in digital manufacturing at HANNOVER MESSE 2024, April 22-26 at booth E17 in Hall 15.

Elevating solutions with strategic partnerships

After our whirlwind discussion of the SAP showcase at HANNOVER MESSE 2024, a key topic arises in the conversation. The fundamental importance of strategic partnerships and a robust partner ecosystem stands out. It is for instance, after all, a collaboration between SAP and KINEXON that will transform the AGV solutions currently available on the market.

SAP embraces its prominent position in the global market to invest in, and thereby empower, its partners – benefitting the entire supply chain ecosystem in the process. Here, Johannes, Ralf and Dominik highlight some partners as demonstrative of the power of collaboration: All for One, BearingPoint, Camelot ITLab, Capgemini and proaxia all add tremendous value as SAP partners. For further insights into how these companies collaborate with SAP as partners, explore the spotlights dotted throughout this article.

“All our partners, whether they’re related to supply chain or to SAP more broadly, have always been fundamental to us as

a business,” says Johannes. “But now more than ever we recognise that these strategic alliances will continue to grow in importance as we develop together. We have many different types of partners, from system integrators to software partners. All of them are relevant today and into the future, because we realise within SAP that due to the high demand from our customers, we have to entrust our partners with further responsibilities along the customer value lifecycle.

“One of our fundamental beliefs as a company is we can only expand our expectations and ambitions when we also grow with our partners: together and in all aspects.”

Ralf reiterates the notion of the responsibility SAP embraces towards its partners.

“Since we are a leader in the market, customers expect SAP to talk and engage with our huge ecosystem,” explains Ralf. “By working with an amazing partner ecosystem we can tailor and amplify our solutions for our customers, across industries and lines of business, understanding and then meeting customer needs and helping them thrive in the process.”

Where next?

Looking ahead to the future, Johannes, Ralf and Dominik offer their insights on the direction of digital supply chain strategy at SAP in the coming years.

57

“First, the future of the digital supply chain strategy at SAP is to embrace business AI and generative AI, with an end goal of improving our supply chain offerings,” says Johannes. “Second, this goes hand in hand with the transformation of ERP into the cloud. Our goal is to show our customers the distinct, industryspecific value proposition of cloud ERP transformation. Third, within our entire design-to-operate solution area the goal is to be the best-inclass solution, offering an end-toend seamless experience. Fourth, an important SAP message for 2024 is ‘Accelerating our success together.’ We are driven by the idea that we can only be successful in concert with the entire SAP ecosystem, including our partners, SAP employees, and customer base. Finally, we will continue to listen to our customers through feedback sessions, so we can continuously improve our offerings in relevant, industry-specific and profound ways.”

Ralf highlights the burgeoning importance of risk management and visibility for customers, while simultaneously encouraging them to consider all external and contextual factors in their operations.

“Of course, we must prioritise our customer’s internal integration with SAP, but we cannot neglect external forces,” notes Ralf. “For instance, with risk management, how can we

help our clients untangle challenges and perceive them in a simple, understandable way? How can we help them consider all the global economic factors that impact their business? Ultimately, how can we wield analytics and the insights it brings to secure the best performance and outcomes for our customers? We expect AI, and specifically business AI, to play a crucial role in these areas in the coming years.”

Dominik believes the future of supply chain is near autonomy, powered by artificial intelligence and a wealth of data.

“For me, this means that the silos in supply chains will continue to converge,” says Dominik. “Because if you have all the data at your fingertips – whether you’re a business expert, supply chain planner, demand planner, logistical dispatcher, service technician or purchaser – having all of this data at your fingertips while running autonomous processes means that teams can converge. I believe this means we can cover much more intelligence and empower our customers to do what they can do best.”

For further information about SAP, visit sap.com.

To meet and connect with SAP at HANNOVER MESSE 2024, April 22-26, at booth E17 in Hall 15 – head on over to the event overview page on their website.

58

Added Value

Johannes

Johannes embraces being value-driven, compassionate and open-minded during a customer lifetime value journey.

“Ultimately I see this approach as the best way to engage with our customers,” says Johannes. “When we work with customers, we have high ambitions for bringing them the optimal end-to-end solutions for their needs. But we also need to remember they are often embarking on a new journey, which can be intimidating. By being compassionate and openminded as well as value-driven, we foster trust and encourage customers to embrace change.”

Connect with Johannes

Ralf

Ralf emphasises the importance of teamwork and relishes the opportunity to embrace a leadership role at SAP.

“It’s a pleasure to be ‘the captain of the boat’ and guide my team. It’s about navigating new waters and I love this side of my role,” says Ralf. “Working with new companies and new challenges is energising. But you can only reach new destinations with collaboration – internally but also with your partners and customers on board too.”

Connect with Ralf

Dominik

Dominik inspires creativity to address complex business challenges.

“I am deeply passionate about fostering creativity and empowering individuals to unlock their full potential,” says Dominik. “Guiding professionals is not just about providing direction, but also about cultivating an environment where innovation flourishes. Through compassion, collaboration and a commitment to nurturing diverse perspectives, I aim to inspire and lead creative individuals towards meaningful outcomes that push boundaries and drive positive change.”

Connect with Dominik

60 Walmart Central America Director Supply Chain & Manufacturing and Growth discusses their customerdriven, global supply chain approach Walmart Central America Director Supply Chain & Manufacturing and Growth discusses their customerdriven, global supply chain approach

61

MISS AN ISSUE SIGN UP FOR FREE!

Director of Manufacturing Strategy customerapproach Director of Manufacturing Strategy customerapproach

Produced by NEVER

SUBSCRIBE

BUSINESS INTERVIEW

Consolidating procurement in the public sector to drive innovation and sustainability

Simon Bullimore, Head of Group Procurement at Norse Group on the company’s organisational approach to procurement in the UK public sector.

he Norse Group is the largest Local Authority Trading Company (LATCO) in the UK, and it aims to improve people’s lives while generating ethical, sustainable profit for the public sector. In a context of cost pressures posing significant service challenges for councils and public bodies, Norse Group’s unique partnership approach to flexible service provision provides abundant opportunities to design and execute collaborative solutions.

Norse Group supplies a significant number of services including catering, grounds maintenance,

highway maintenance, transport, security, fleet management, facilities, cleaning, consultancy and adult social care.

Each one of these areas has its own supply chain, and Simon Bullimore, Head of Group Procurement at Norse Group oversees all of them. Simon joins us today to discuss the Group’s complex supply chain network and how it embraces consolidation, technological innovation and sustainability in its operations.

“So not only do we supply an array of services and sectors, but we also do it by what we call joint ventures

“We are developing a new computer system across the Group which will give us much better management of the information and data from our supply chain”

with several local councils in the UK,” begins Simon. “A joint venture model is a dynamic and reliable model for local councils. We spend in the region of £187m per year on products and services, and given the number of sectors we're in, we've got an extremely diverse supply chain. As such, cost control, governance, sourcing, tendering and the whole procurement cycle sits with me and my team –there’s no real element we don't cover.”

Simon explains that Norse Group takes a consolidated approach to procurement to ensure success in light of its expansive and complex supply chain.

“Since the Group merged in 2019 to gain efficiencies and improve services for customers, breaking down silos and integrating the business has been a priority,” says Simon. “This is understandable as all these areas have their own profits and losses to consider, plus they are trusted to run their own areas of the Group.

“But procurement is a function that touches and helps empower every single part of Norse Group. We cover a huge amount of ground and it's only recently that we are starting to really pull together and leverage our spend. Part of my role is to laud the benefits of joined-up procurement, especially while we're trying to achieve progress and results in the current economic climate.

“A consolidated approach to procurement is essential due to the nature of public sector governance and also meeting the commitments we make to ESG. Our targets simply cannot be achieved across a widespread and non-controlled supply chain.

“Our colleagues are starting to realise as well that everyone across the business wants to deal with the best suppliers, and the reliable

aspects of volume and spend still shout the loudest for attention. But our consolidated approach to procurement makes us an attractive organisation to work with and that's the key: be that in how we handle supplier management, consolidated group spend or streamlining our supply chain.”

So what are some of the key projects underway at Norse Group where the consolidated approach to procurement is unfolding? Here, Simon highlights the Group’s approach to ESG.

“As with all businesses, we take the ESG side of our operations very seriously,” says Simon. “We've always had obligations as a Group because of our position as a LATCO and our Norfolk County Council ownership. So we've always been up to speed on aspects like sustainability and the Slavery Act or Bribery Act, right from the beginning.

“A recent project within our supply chain governance relates to one of the biggest risks with modern day slavery: the overseas textile market,” says Simon. “Here we've worked to engage with businesses that are SA8000® accredited and part of the Sustainable Textile & Leather Production scheme (STeP scheme). STeP accreditation recognises adherence to best practice approaches to safety, ethics and sustainable production within all manufacturing facilities.

“Our CEO, Justin Galliford, drives a lot of our ambitions in net zero and carbon emissions – our target is to