Understanding the various kinds of foam insulation available and their proper application requires a PHD! Below is a breakdown of the two primary types of insulating foam in our industry: polyurethane and extruded polystyrene (XPS), along with details about their thermal performance over time.

KPS Global utilizes closed cell polyurethane foam insulation in their panels.The polyurethane insulation creates a lightweight, structural amalgamated panel. Amalgamated means to combine or unite to form one structure which is why this is ideal for building structures as the foam has adhesive properties which bond the metal skins and the frame together as it cures.

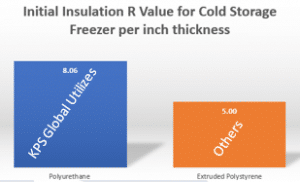

Many ask why is closed-cell polyurethane insulation recommended for use in cold storage building structures. First, it has the highest R-Value of any insulation used in the industry, up to R-8.06 per inch thickness, and is the reason why KPS Global utilizes this kind of insulation. That compares to an R-5 insulating value per inch thickness for the nearest competitor extruded polystyrene (XPS). See Figure 1.

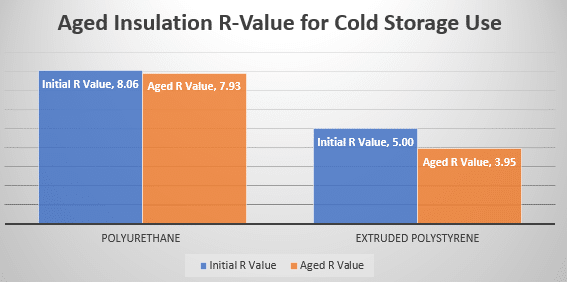

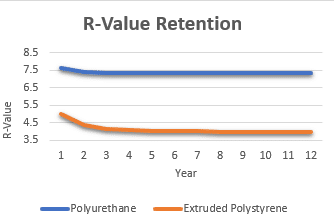

Secondly, it retains this high thermal performance better than any other insulation. Both polyurethane and XPS foam can lose a portion of its insulative value over time due to refrigerant gas diffusion with atmospheric gases. However, a recent study where polyurethane insulation samples were extracted from decommissioned cold storage units found over an average use life of 11.78 years, the polyurethane foam only lost an average of 1.55% of its thermal performance in freezers panels and 5.86% in cooler panels.1 Diffusion in the KPS Global panels was limited because the polyurethane insulation is bonded to the metal skins and panel frames where atmospheric gases are restricted from interacting with the insulation.1

Secondly, it retains this high thermal performance better than any other insulation. Both polyurethane and XPS foam can lose a portion of its insulative value over time due to refrigerant gas diffusion with atmospheric gases. However, a recent study where polyurethane insulation samples were extracted from decommissioned cold storage units found over an average use life of 11.78 years, the polyurethane foam only lost an average of 1.55% of its thermal performance in freezers panels and 5.86% in cooler panels.1 Diffusion in the KPS Global panels was limited because the polyurethane insulation is bonded to the metal skins and panel frames where atmospheric gases are restricted from interacting with the insulation.1

A long-term thermal performance study of extruded polystyrene by manufacturer DOW showed XPS insulation lost an average of 21% of its insulating value over a 12-year period falling to a net R-Value of 3.95 per inch.2 KPS Global freezer panels averaged long-term insulating value is R-7.93. That means the KPS Global polyurethane can provide a long-term insulating performance 100% better than extruded polystyrene (XPS) insulation (Figures 2 & 3).

Thirdly, the polyurethane insulation bonds all the panel components together creating a structural insulated panel. This can eliminate the need for structural steel supports in larger cold storage enclosures.

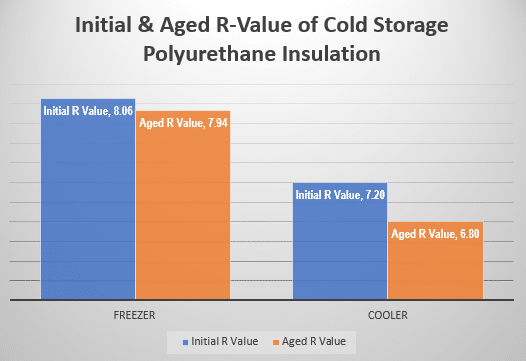

While aerogel and vacuum panels offer great insulative performance in certain applications such as ice chests and thermos bottles, their insulation is not manufactured for structural uses. Closed cell polyurethane is in fact the highest performing insulation used in the construction of structural insulated panels for coolers and freezers. Since polyurethane can deliver an insulative value of up to R-8.06 per inch thickness, the KPS Global 5” thick freezer panel can provide an insulative value up to R-40. Below (Figure 4) is a comparison of Polyurethane (what KPS Global uses) insulation initial and aged R-Values for Freezers and Coolers.

Polyurethane foam withstands physical attacks and stresses better than polystyrene as well as performs better in load bearing and thermal control application. It is also a cost-effective solution which is one reason why polyurethane is the most specified insulation for cold storage applications.

1Costanza, J. (2015). Environmental and Economic Assessment of Reclaimed Polyurethane Panels: The Case of Diverting Decommissioned Cold Storage Panels From Landfills and Recycling Into Three Forms of Insulative Building Materials.

2Chau, V., Paquet, A. (2004). An Evaluation of the Thermal Conductivity of Extruded Polystyrene Foam Blown with HFC-134a or HCFC-142b. The Dow Chemical Company, Midland, MI 48674

3BASF. (2010). Technical Product Data. Elastopor P 19080R Resin/Elastopor P 1001U Isocyanate Rigid Urethane Foam System. 1419 Biddle Avenue, Wyandotte, MI 48192