It can be frustrating and alarming when your walk-in displays visible damage. Replacing a walk-in is no small project and requires quite a bit of time and money. Luckily, there are a variety of different restoration solutions that can help extend the life of your walk-in, including batten strips. Batten strips are used to reseal panel joints and re-insulate walk-ins to help slow down the effects of damaged panels and improve both performance and functionality. This blog explores how to utilize batten strips and help extend the life of your walk-in.

What Are Batten Strips?

Batten strips are made of 26-gauge metal and are attached to the interior or exterior walk-in panel joints using screws. They are used to reseal the joints of the panels and provide an extra layer of insulation. Batten strips slow down the effects of already damaged panels and defend against vapor infiltration, condensation, and the icing of joint spaces.

When Are They Used?

If you can visibly see damage at the joints or if the panel seems to be swelling and you want a quick and cost-effective fix, batten strips can do the trick. Think of a batten strip like a band-aid. Band-aids are placed on an open wound to conceal the injured area and prevent the affected area from getting any worse by blocking bacteria. Batten strips work almost the same way; the large metal sheets go over the damaged areas of the panels to protect the walk-in from any more damage and provide another layer of insulation.

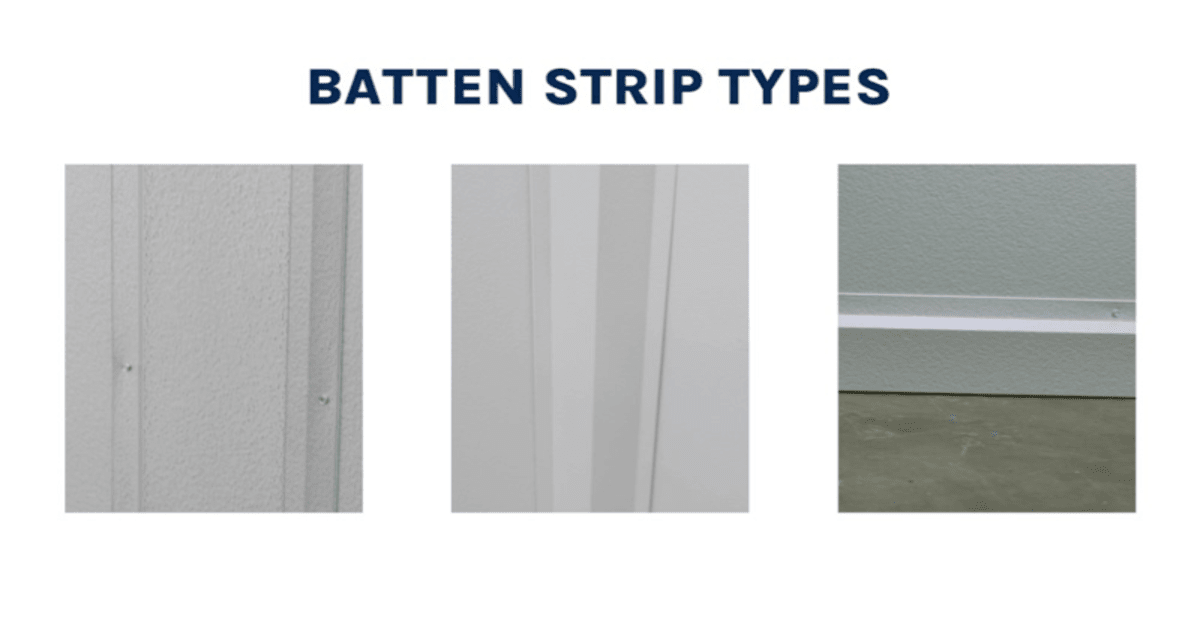

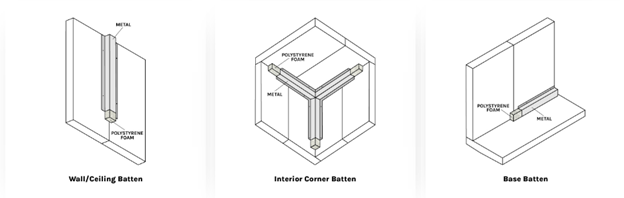

Three Types of Batten Strips

There are three different types of batten strips, including wall/ceiling, interior corner batten, and base batten. The type of batten strip needed depends on the location of the damaged joints. The areas on a walk-in that are displaying joint displacement or panel swelling, or any similar damage, can be reinsulated by placing batten strips over the damaged joints.

Installation Process

Batten strips that are ordered from KPS Global come complete with a batten strip kit for installation. The kits include butyl, silicone, venture tape, screws, EPS Foam, and a 10-foot, 26 gauge metal batten. All batten strips come in 10-foot-long pieces that are then cut to the exact size needed during the onsite installation. Our battens are engineered for a seamless installation process using screws and butyl to secure them in place.

Why Should You Use Batten Strips?

When you start to see damage at the panel joints, the effectiveness of the walk-in is going to decrease. As a result, the walk-in may not work effectively. Knowing the importance of walk-in coolers, having a functioning unit is key. Replacing the walk-in is a large investment in time and money and is often not an option. On the other hand, batten strips can quickly be ordered, installed, and reinsulate the joint in a short period of time.

Click here to order batten strips from our store, or visit our website for more information on our restoration solutions.