When designing a walk-in, there are a variety of customization aspects involved in the process, including the floor panels. Floor panels are manufactured similarly to wall and ceiling panels but have a variety of different options according to intended use and load requirements. It is important to have the right floor depending on if it’s a cooler or freezer.

The knowledgeable experts at KPS Global will provide the right floor panel options that meets the requirements of the application, use and spec of the walk-in creating a complete insulated panel system.

This blog serves as guide on understanding the various floor panel options for your walk-in offered by KPS Global.

Things To Consider For Walk-In Floors

Choosing the right flooring for your walk-in cooler and freezer is essential for ensuring optimal functionality and efficiency. Several factors should be considered during the decision-making process such as:

- Location

- Risk of Moisture Buildup

- Access In and Out (Ramps)

- Traffic

Considering these factors will help you select the most suitable flooring option for your walk-in cooler or freezer, ensuring efficient operation and product preservation.

Does A Walk-In Need A Floor?

Most walk-in applications do require floor panels especially when dealing with products that need to be stored in colder environments. For certain applications such as foodservice, insulated floor panels are necessary to not only keeping food from spoiling but also meeting NSF certifications. For walk-in freezers insulated floor panels or a concrete floor are necessary to meet specs and prevent frost heaving.

Floor Panel Traffic

Each floor panel provided is based on the intended use and given load of the walk-in as noted previously.

When choosing a walk-in floor, it is important to consider the type of traffic the unit will have. Not all floor options can withstand the same traffic. Units designed for foot traffic will have much different options for floor construction and finish than a unit intended for forklift traffic. Understanding the type of traffic (foot traffic, pallet jacket, fork lift, etc) will help ensure you receive the right floor panel option to operate effectively.

Foot Traffic

For walk-in projects with foot traffic only, the standard floor supplied is a metal panel construction of either 18 Gauge Galvanized metal or 20 Gauge Stainless Steel finish over foam.

Hand Truck

For hand truck traffic inside the walk-in, the floor panels are constructed with ½” of plywood under any standard metal finish.

Pallet Jack

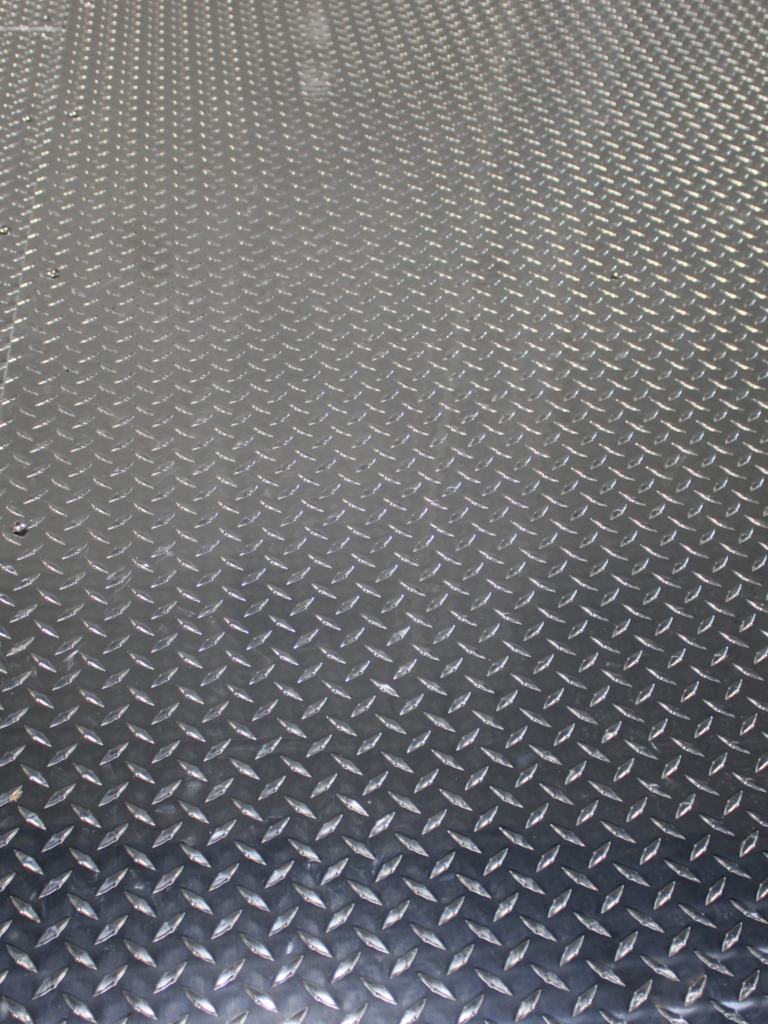

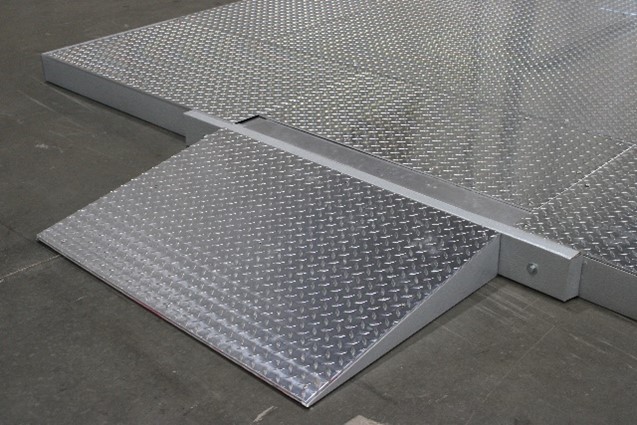

Projects intended for pallet jack traffic in the walk-in are constructed in the same manner as hand truck traffic but with field applied 3/16” Diamond Tread Aluminum.

Super Floor

For projects categorized as needing a Super Floor, we use a ¾’ plywood with stiffeners at 12” on center and field applied 3/16” Diamond Tread Aluminum for motorized walk-behind lifts.

Forklift Traffic

For forklift traffic inside a walk-in, you can do a floor panel under an insulated concrete slab.

The Finish Options

KPS Global floor panels include different finish options based on the given requirements.

Finish options are determined by the intended use and load requirements of the walk-in. KPSG will recommend the right finish options.

There are five different finish options used for the variety of floor panels depending on use, including:

- 18 Gauge Smooth Natural Galvanized

- 0.050 Smooth Natural Aluminum

- 0.080 Low Profile Aluminum Tread Plate

- 22 Gauge Smooth Stainless Steel Type 304 Stainless Steel #2B Matte Finish,

- Field applied 3/16” Diamond Tread Aluminum

How Is A Walk-In Floor Panel Constructed?

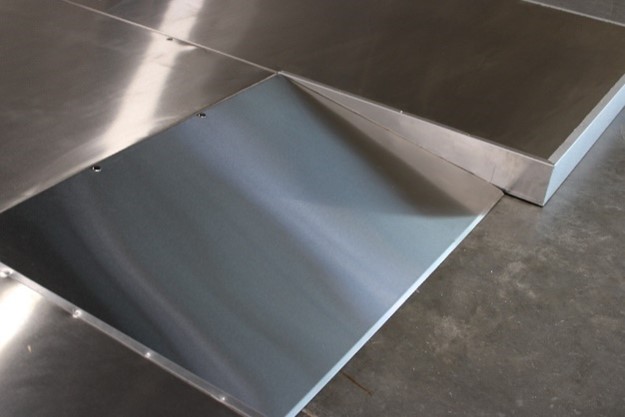

KPS Global floor panels are constructed in a similar manner as walk-in panels with two metal skins with a wood or HDR frame around a poured-in place polyurethane core.

However, floor panel construction is guided by application and traffic on the floor of the walk-in. Additional structural support is offered based on load requirements of the project.

The floor panel types provided are based on the intended traffic requirement and their corresponding uniform load requirements:

- Foot Traffic

- Hand Truck

- Pallet Jack

- Super Floor

When designing a walk-in the decision of whether to have insulated floors or no floors at all is a crucial consideration. Insulated floor panels play a vital role in maintaining the desired temperature and preventing the transfer of external heat or cold into the unit. They are especially important in applications like foodservice, where preventing spoilage and meeting certifications are top priorities.

However, in some cases, walk-in setups with concrete floors may not require separate insulated floor panels. Understanding the advantages and disadvantages of having insulated floors versus no floors can help make an informed decision that best suits your specific needs.

Installation Location

The location of the floor itself is extremely important to ensure proper insulation and maintain temperature consistency. Walk-ins are easily susceptible to the effects of environments they are in, such as a restaurant kitchen. Warehouse, retail store etc. The temperature outside the unit is typically set to warmer temperatures and by having an insulated floors the risk of competing temperatures is much lower

Additional Floor Panel Option: Ramps

In addition to the floor panel options, ramps are an additional feature customers can add to their walk-in design. Ramps are often utilized to make loading and unloading easier for employees. Ramps can be provided to the interior or exterior of the floor panel design. Any ramps provided will be constructed in the same manner as the floor panel design.

Interior Ramp

Exterior Ramp

NSF Requirements For Floor Panels

The intended use of the walk-in can require NSF requirements for the floor panels that need to be met. Floor panels for foodservice applications are constructed to meet NSF requirements. For foodservice areas intended to store packaged food must meet the NSF requirements for “packaged product” and are provide a standard finish of 0.50 Low Profile Aluminum.

Food prep area applications dealing with raw food are required to meet “Splash Zone” NSF requirements. The standard finish provided for this NSF requirement is the 0.050 Smooth Aluminum and the optional is 0.080 Low Profile Aluminum.