In challenging times like these, when supply chains are restrained and panel replacement is not an option, KPS Global can offer alternative non-polyurethane foam products to get you through the foam crisis.

Whether your unit is displaying joint displacement, running inefficiently or struggling to pass health inspections, KPSG’s thermal liner panels and batten strips provide quick, cost-effective alternatives for walk-in coolers and freezers to maintain operations until polyurethane foam becomes available.

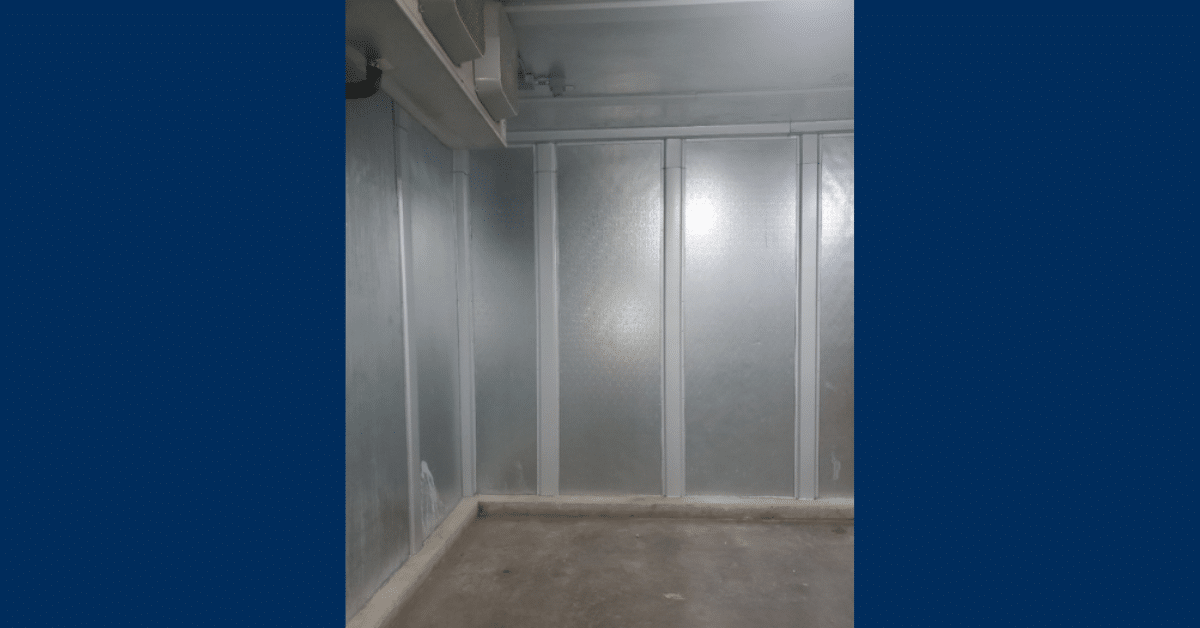

Thermal Liner Panels

Thermal liner panels act as an insulated wallpaper that is affixed to the interior of a walk-in. They improve a walk-in’s thermal performance and provide a fresh new look, bringing it up to spec and ensuring it is ready for the next health inspection.

Designed to reface and insulate existing cold storage panels, thermal liner panels from KPSG can improve panel appearance and extend the life of your existing walk-in.

Constructed of a durable panel face material bonded to an insulated (non-polyurethane) core and attached by a proprietary strip assembly system that includes an integral gasket seal, KPSG’s thermal liner panels are a non-invasive solution that can be professionally installed with minimum downtime. They simply wrap the existing panels to provide an aesthetically pleasing additional layer of insulation that adds an additional R-value of up to 5 to your current unit.

Offered in embossed aluminum-zinc alloy steel, our 47” wide panels are available in both ¾” inch and 2” thicknesses and in 10’ lengths that are field cut according to exact project specs, enabling a customized fit over your existing walk-in panels—even for most non-KPSG cold storage units.

|  |

| Before Application of Liner Panel | After Application of Liner Panel |

When compared to a complete walk-in replacement, KPSG’s thermal panel liners are a quick, cost-effective alternative that helps comply with health code standards.

Batten Strips

Serving as protective barriers, KPSG’s batten strips are engineered to reseal panel joints and reinsulate walk-ins, slowing down the effects of damaged panels, improving appearance and extending longevity. They do so by defending walk-ins from vapor infiltration, condensation development and icing of joint spaces.

Battens are constructed of a 26-gauge metal strip and expanded polystyrene (EPS) foam. They are attached to existing panel joints with screws and butyl. The strips measure approximately three to five inches wide and only protrude ¾ of an inch to 3 inches. Battens with a depth of ¾ of an inch deliver an R-value of 3, while battens with a depth of 3 inches deliver an R-value of 12.

The batten installation process takes place onsite: first, the installer applies butyl in the joint and covers it with venture tape. Next, the installer holds the expanded polystyrene (EPS) foam over the joint while placing the metal batten over the foam and screwing it onto the panel.

|  |

| Before Application of Batten Strips | After Application of Batten Strips |

Offering a simple solution, battens can reseal any joint on your walk-in. They can be mounted internally or externally; however, an external application is most effective in keeping warm air and condensation out of the walk-in’s joints.

Staying the Course

Utilizing KPSG’s thermal liner panels and batten strips provides an alternative solution to projects needing a remodel until the polyurethane foam shortage ends and a full remodel is possible.

Contact us to place you order today or to determine which solution will work best for you.