Commercial kitchen refrigeration plays an essential part in food safety, especially in foodservice operations where large quantities of perishable goods pass through the kitchens of restaurants, central kitchens, stadiums, universities, hotels and more.

In this blog, we’ll review the elements of commercial refrigeration.

How does refrigeration work?

Commercial kitchen walk-ins are highly insulated envelopes constructed of panels made with insulative foam to resist the flow of heat. They are kept cold by refrigeration systems. Here’s how refrigeration works:

The principle of refrigeration and cooling involves removing heat from one region and depositing it in another. When you pass a low-temperature liquid close to objects that you want to cool, heat from those objects is transferred to the liquid, which evaporates and takes away the heat in the process.

You may already know that gases heat up when you compress them and cool down when they are allowed to expand.

Refrigeration systems function using the principles of pressure, condensing and evaporation of a fluid (the refrigerant) in a closed circuit to remove heat and reduce the temperature inside the walk-in.

Here’s what each key component in the system does:

Compressor: Gas at a low pressure and low temperature enters the compressor. The gas is compressed to a higher pressure and its temperature rises. This process uses electricity.

Condenser: The hot gas is then transferred to a condenser where the heat is removed, and the gas begins to condense into a liquid. The heat is released via cooling fins on the back of the refrigeration unit.

Expansion valve: The liquid then goes through an expansion device where its pressure is suddenly lowered, it expands and some of the liquid turns very quickly into a vapor. This change of state has a cooling effect.

Refrigeration Maintenance Tips

Now that you understand how refrigeration systems work, here’s a list of helpful tips to help you maintain your walk-in cooler.

1. Consistently clean the interior and exterior of your unit. Keep all surfaces clean and free of spilled liquid and food particles.

2. Regularly clean the condenser coil. If it gets dusty or dirty, it will struggle to maintain temperature which could ultimately lead to component failure.

3. Check the area by the evaporator coil. Like the condenser coil, the evaporator coil is a crucial component to your commercial kitchen equipment. The evaporator coil is located by the evaporator fan and absorbs heat as warm air passes through the refrigeration system, helping cool the walk-in’s interior. Make sure to keep the area surrounding the coil consistently clear and clean. Blocking the airflow by the vents inside the unit can cause the coil to freeze, leading to water leaks and a rise in temperature.

4. Check gaskets often. Door gaskets are essential to any walk-in. Any issue with a gasket can prevent the walk-in door from sealing shut, which allows air to flow in and out of the unit. If a gasket is ruined, replace it!

KPS Global Is Here to Help

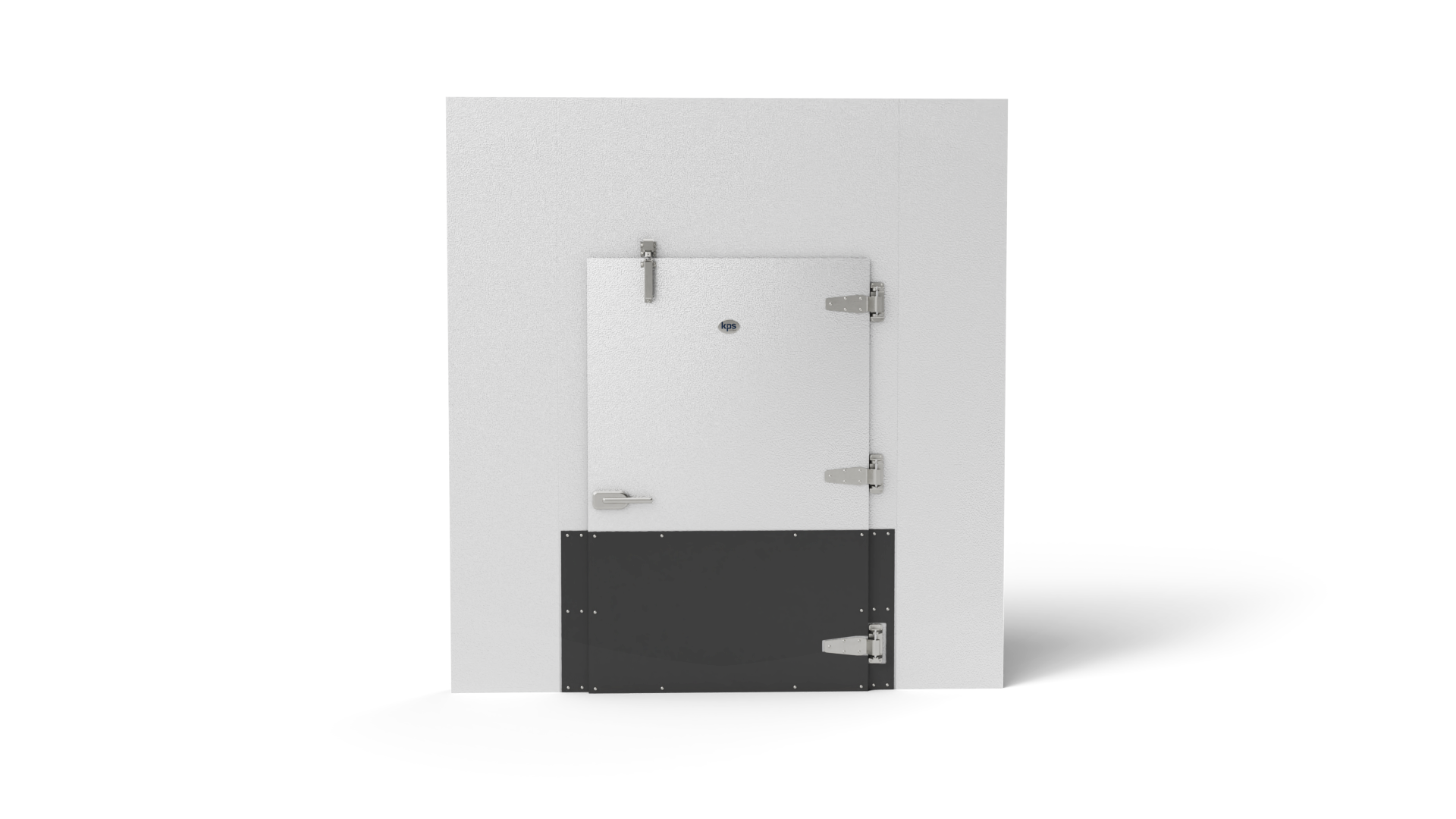

Walk-in coolers and freezers are a critical component in the kitchen, and you must have the right refrigeration system to ensure efficient operations. KPS Global provides recommendations on sizing from test fit plans.

Bringing our teams in early allows us to do load calculations and make recommendations on the size of the unit(s). From there, KPS Global provides spec sheets from the manufacturers for utility information to assist with mechanical and electrical drawings.

From remote, self-contained, or hybrid units, KPS Global is vendor agnostic to help you find the right solution for your commercial kitchen. KPS Global knows cold storage for foodservice jobs.

Contact us for help with your next project!