KPS Global® and Hillphoenix have collectively released a whitepaper entitled “Meet Me at the Intersection of Technology and Humanity,” covering their collaborative and innovative work with the Vermont Food Bank.

The Vermont Food Bank was facing several significant operational challenges, driven by shifts in the types and volumes of donated goods they received. The organization was receiving large quantities of fresh, perishable goods that need to be properly stored in a large, refrigerated facility.

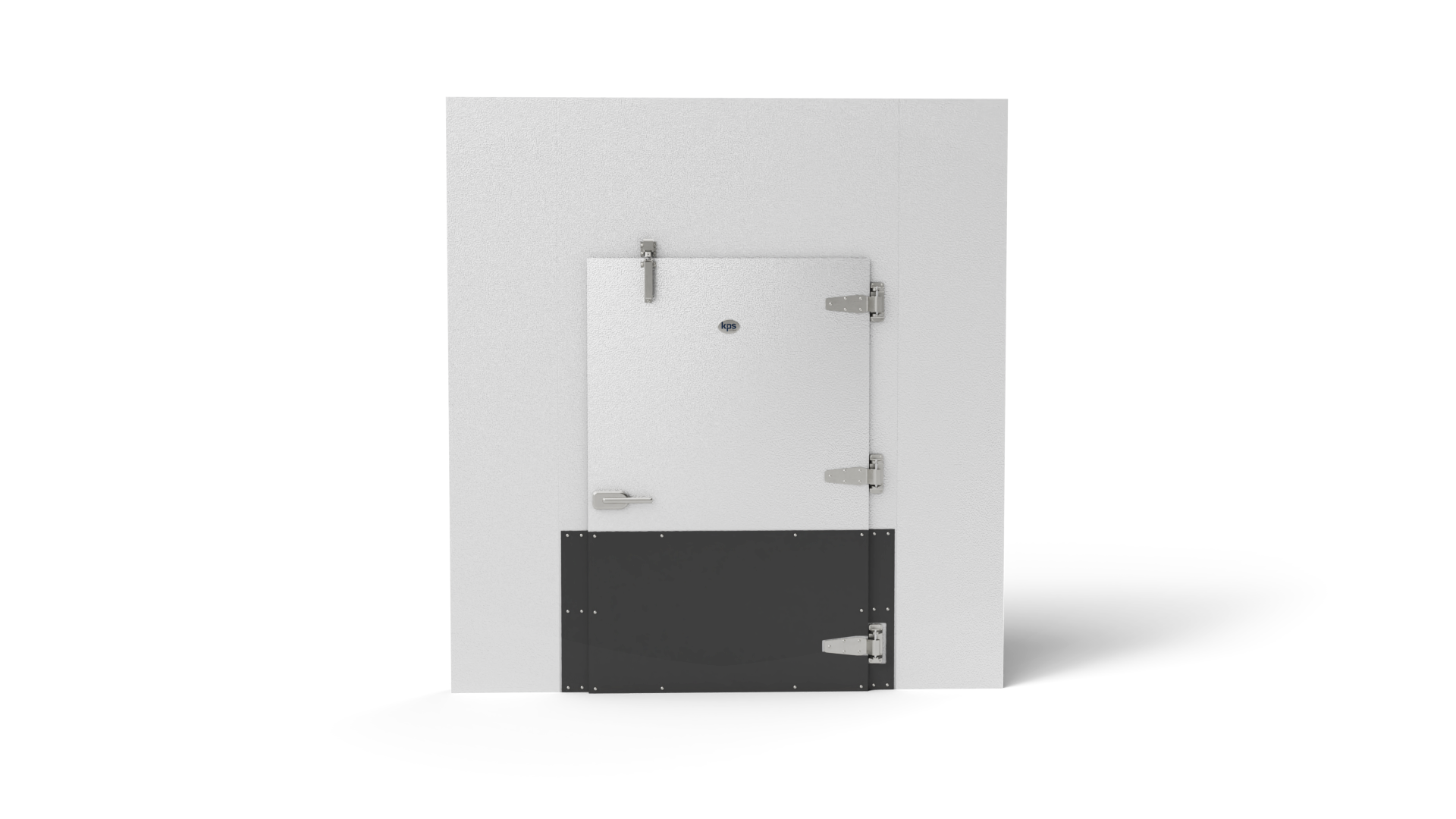

KPS Global worked with the Vermont Food Bank to increase the facility size to accommodate the growth in volume in an efficient manner and recommended Hillphoenix to provide a refrigeration system.

Read more about the collaboration that revolutionized the Vermont Food Bank’s operation below!

Nationally, Hunger in America 2014 (the largest and most comprehensive insight study into charitable food distribution in the United States) found that more than 46 million people turn every year to agencies and programs of Feeding America, a network of over 200 food banks. The Vermont Food Bank, which opened its doors in 1986, has been a member of that network since 1994. Their mission statement is straightforward — “to gather and share quality food and nurture partnerships so that no one in Vermont will go hungry.”

Deeming this as a “lofty” goal would be an understatement. Nicole Whalen, director of communications and public affairs for Vermont Food Bank, dimensions the challenge for the state of Vermont alone with some eye-popping statistics:

- 1 in every 4 Vermonters, or an estimated 153,000 residents, have a hunger problem requiring them to turn to food shelves and meal service programs.

- This includes 33,900 children and 26,010 seniors.

The bottom-line need is there are hundreds of thousands of everyday Vermont folks — including children, seniors and working families — who are unable to put enough food on their table to avoid going to bed hungry that night. Enter the Vermont Food Bank who acquires and distributes over 12 million pounds of food each year through 225 network partners around the state — food shelves, pantries, senior meal programs and other community meal sites — utilizing a modest staff and over 1,500 volunteers operating out of three Vermont distribution facilities with the headquarters located in Barre, Vermont.

These herculean efforts have been conducted by the Vermont Food Bank amid a number of significant operational challenges, ranging from a major paradigm shift involving the sources and types of donated food to the current impact and constraints of fulfilling their mission in the midst of the Covid-19 pandemic. The “food banking industry” continues to change in significant ways. Not long ago, donated food came in the form of trailer loads of “salvage” involving dry goods from the grocery industry. However, the emergence of “secondary food markets”, with channels like factory outlets, off-price and discount stores, dollar stores, flea markets and online auction houses, provided food retailers with an option for disposal of their surplus where they still would receive some revenue stream in return. Almost overnight, the Vermont Food Bank saw a migration from receiving donated, nonperishable goods to receiving perishable types of food from diverse sources like farms, individual food retail stores, and small processors.

The Vermont Food Bank (VFB) was at a crossroads. Now staring at large quantities of fresh, perishable food that had to be properly managed and maintained with refrigeration, along with an old facility with insufficient space and lacking other key capabilities, and still working to an out-of-date business model incapable of handling the efficiencies mandated by this “new world”, decisions had to be made and actions had to be taken. In the words of Nicole Whalen, “These were unprecedented times that demanded an organization capable of creativity, innovation and inspiration — and we had just the right team for the job!”

Nicole and the VFB team, under the leadership of Jason Maring, chief operations officer, realized that they first needed a comprehensive plan to achieve the required degree of change. They formulated a “Capital Campaign” with primary focus on three elements:

- Refrigeration – providing the capability to properly control temperatures and efficiently manage the large quantities of fresh, perishable foods they were now receiving.

- Expansion – increase the facility size to accommodate the growth in volume in an efficient manner. Putting this in perspective, fresh produce distribution alone by VFB increased from less than 250,000 pounds in 2004 to over 2.2 million pounds in 2019!

- Renovation – broad-based in scope, ranging from altering physical facilities to organizational structure to their business model with its everyday process for conducting their mission.

Once the Capital Campaign was underway, VFB took the first steps of adding square footage to their facilities to achieve the desired expansion and turned their attention to the refrigeration need — what technology existed out there that could best meet their need to serve humanity?

Initially, KPS Global, an industry-leading manufacturer of insulated panel systems and cold, walk-in enclosures, worked together with VFB. They, in turn, suggested Hillphoenix, a leading manufacturer of display cases, specialty products, commercial and industrial refrigeration systems, power systems and comprehensive services, to serve as the contractor and source for the refrigeration needs. Jason Maring, VFB’s COO, was able to draw on his prior experience working for a local, prominent, community-owned food cooperative, who employed a Hillphoenix Advansor CO2 Booster System for all their refrigeration needs, to help validate the decision. As Jason recalls, “I had knowledge of some refrigeration companies from my time at the food co-op. Hillphoenix was the popular brand with the solid track record, so I encouraged the architect and builder to reach out to them.”

Collectively, the project team conducted a site visit to the co-op to get a better understanding of the Hillphoenix CO2 system and what kind of opportunity it presented. Their enthusiasm was buoyed by the successful acquisition of financial assistance from Efficiency VT, a state-wide agency dedicated to helping Vermonters achieve energy efficiency and savings. “Our goal was to be as environmentally sustainable as possible while still meeting all the functional and budgetary requirements we had. CO2 offered us reduced system energy cost, invaluable environmental sustainability and responsibility, along with a refrigerant that was non-volatile, inexpensive and devoid of any harmful effects to our planet,” stated Jason. “With the performance and efficiency savings we witnessed at the co-op, along with the financial help we received from Efficiency VT, we were sold on CO2 refrigeration as the technology we needed to achieve our mission,” he concluded.

And so, the intersection of technology and humanity was consummated with the installation and commissioning of the new Hillphoenix Advansor CO2 Booster System by VFB in 2019. Nicole Whalen has many positive things to say about their experience to date with the new refrigeration system, but she likes to encapsulate it all by succinctly putting it in the perspective of the Vermont Food Bank mission — “We have drastically improved our ability to provide needy Vermonters with more fresh food, more efficiently!” she proclaims. Nicole is careful to point out and emphasize that their Capital Campaign is a “work-in-progress” in its initial throes, having made its first few significant steps now, yet having a long way to go. But her enthusiasm for the future of VFB is evident as she points out, “Our new refrigeration system has revolutionized our operation and positioned us well to meet our future needs. It didn’t take us long to realize that we cannot do our important work without it!”

And important work it is indeed. The advent of the Covid-19 virus has created a food security crisis the likes of which we have never seen in our lifetime. Nicole and her team feel up to the task. “These are new waters we are forced to navigate,” she said. “But our creative, innovative, and inspiring organizational response will meet the challenge. To that end, the addition of our Hillphoenix CO2 refrigeration system has been invaluable!”

So, if you’re ever wondering how refrigeration can have a direct and profound impact on the basic needs of humanity — Meet me at the intersection of technology and humanity — Boy, have I got a story to tell you!