Condensation or frost and ice buildup can damage walk-in coolers and freezers, increasing operating costs and resulting in expensive equipment downtime for maintenance interventions. However, retailers can protect their walk-ins and avoid these costs with equipment that is properly outfitted to guard against water vapor: gaskets and butyl.

Unwanted ice formation can occur inside walk-in coolers and freezers when water vapor penetrates through openings or cracks from the outside. This airborne moisture either condenses or freezes, depending on the conditions, resulting in the unit experiencing decreased performance, poor energy use and a shorter life.

The first line of defense against vapor penetration and the ill effects of ice buildup or condensation are gaskets. The gaskets attach to the outer edge of the panel joints. They stop cool air from escaping and ambient moisture from seeping in. The absence of a gasket introduces opportunities for humid air to enter and forces the equipment to run constantly, reducing its efficiency.

Butyl is the second tool used to prevent water vapor intrusion in freezers. The waterproof, synthetic rubber serves as a sealant that is impermeable to air and creates a robust barrier to keep out moisture. It is applied in freezer panel joints (approximately 3/8” bead) to form a protective vapor barrier. Premium grade butyl-based sealant is permanently flexible and non-skinning, making it a superior weapon in the fight against vapor penetration.

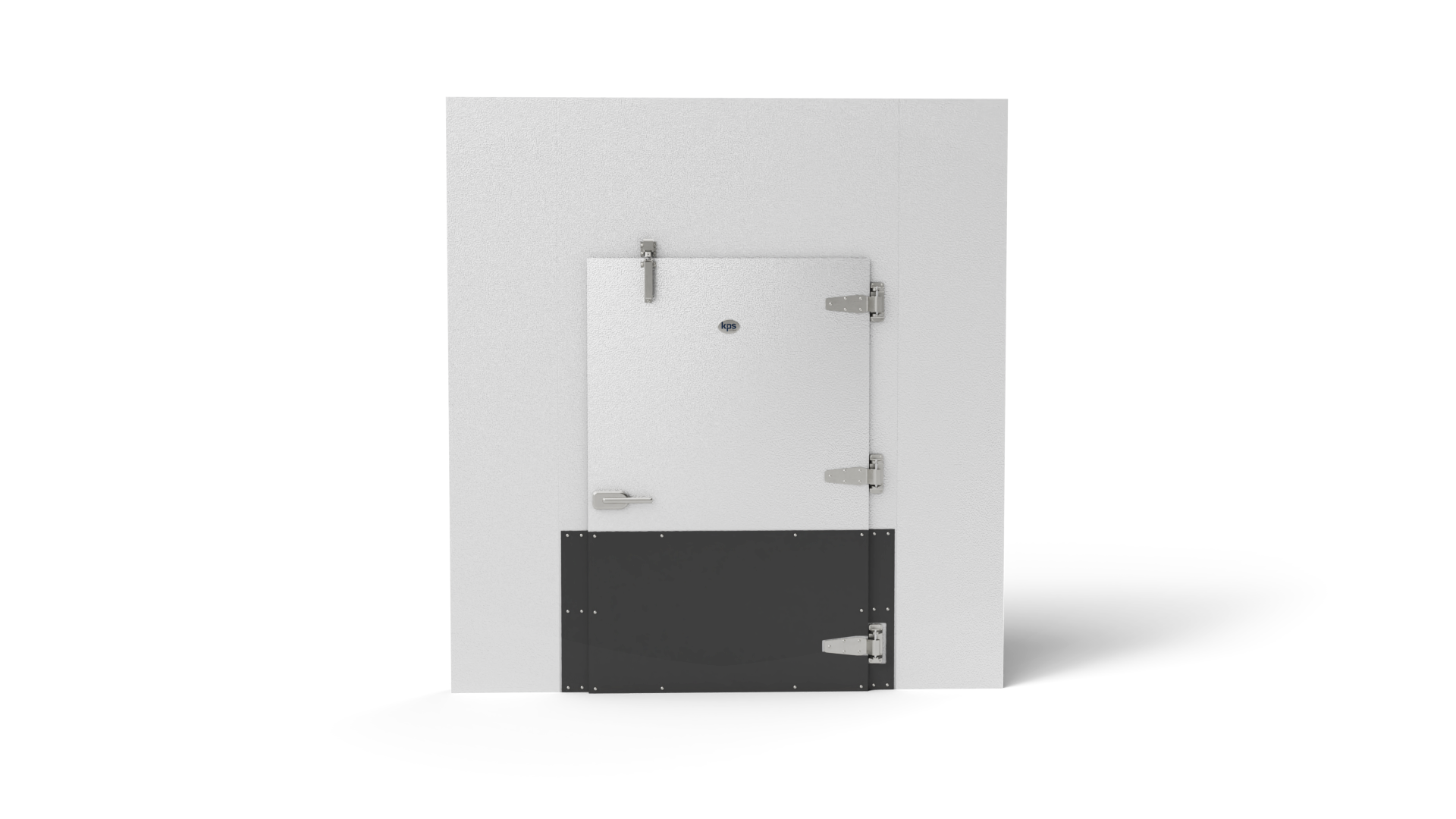

By outfitting a commercial walk-in cooler or freezer with gaskets, and properly applying butyl, you can defend your critical assets from destructive icing. KPS Global is a leading manufacturer of insulated panel systems. Learn more about our walk-in coolers and freezer products on our website.