Current market dynamics continue to affect North American end users of polyurethane foam and their ability to serve customers and meet demands in a timely manner. The unprecedented disruption to the polyurethane foam supply chain has lasted longer than expected as suppliers continuously struggle to increase production and sustain sufficient volumes of chemicals.

As we head into August, key chemicals utilized to create polyurethane foam remain constrained, indicating that this shortage will remain a challenge for the rest of the year.

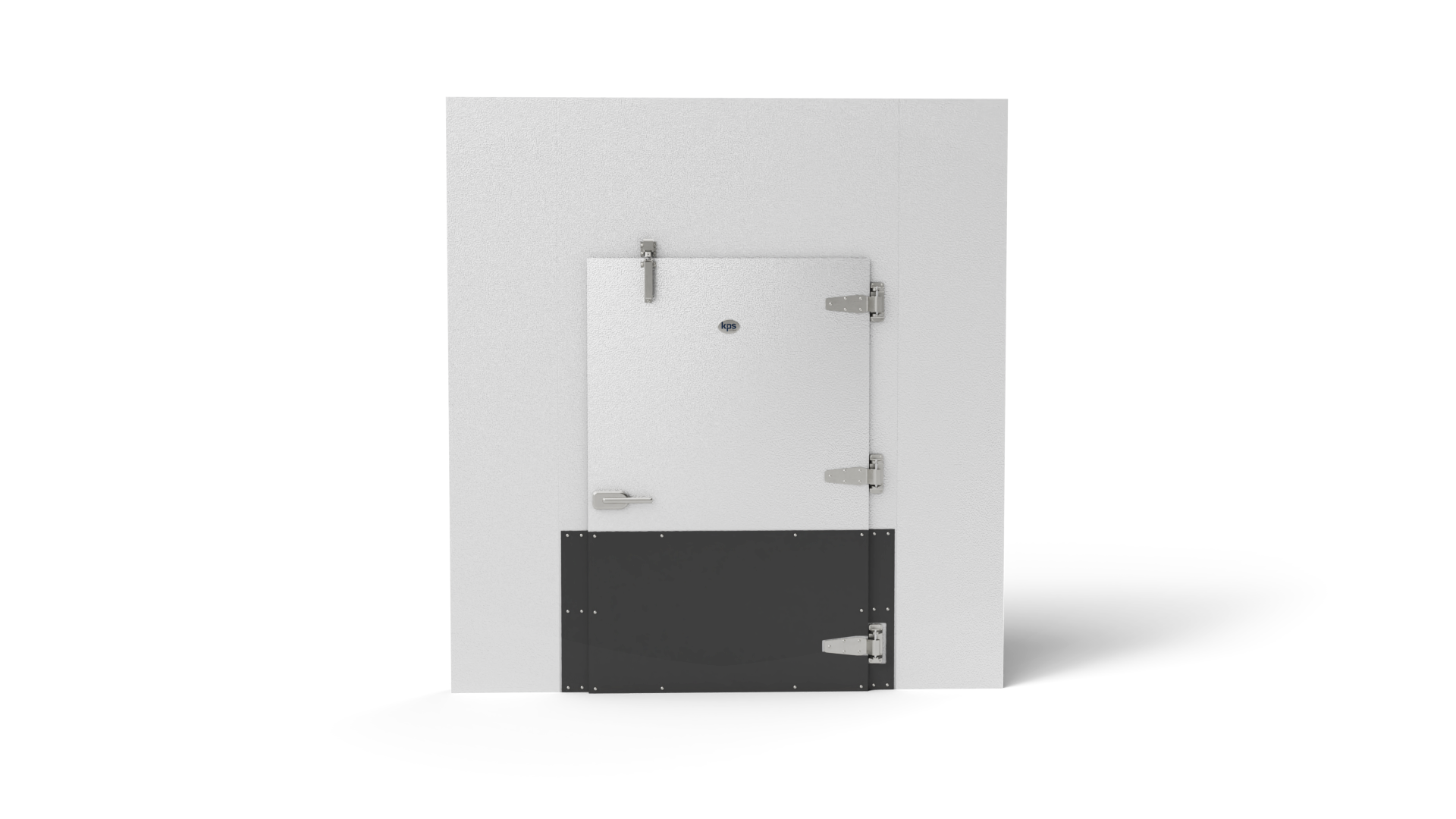

As we move forward during this challenging time, KPS Global is proactively exploring methods to add alternative solutions to help meet our customers’ needs. In addition to offering various alternative products that will allow a walk-in to maintain operations until a full remodel is possible, we are analyzing a potential panel recycling strategy and working with alternative suppliers to test substitute chemical formulations.

Ultimately, as we look forward to returning to normal operations, we want to thank everyone for their cooperation and patience during this frustrating time.