KPS Global custom solutions begin with manufacturing industry-leading structural insulated panel systems to create high-performing temperature-controlled environments. The objective of the insulated panel system is to isolate and control the environment from the outside environment.

KPS Global structural insulated panel systems are manufactured with a high R-Value insulating foam called polyurethane. The closed-cell foam is injected into an empty shell comprised of two metal skins and perimeter frame components

A blowing agent blended into the polyurethane foam turns the rigid polyurethane plastic into a high-performing insulation. The blowing agent creates millions of tiny gas-filled cells in each cubic inch of the foam which is highly effective in slowing down thermal energy transfer. The polyurethane foam blowing agent is the reason why polyurethane insulation has the highest R-value of any building insulation.

In this blog you will learn the ins and outs of thermal bridging and thermal breaks, what they are, how they work and how they may influence energy costs.

THE SCIENCE OF HEAT TRANSFER

Thermodynamics

The laws of thermodynamics tell us that heat energy always seeks to equalize when a temperature difference exists between two bodies. It is like a glass of iced tea sitting on an outdoor patio table during a summer afternoon. The iced tea absorbs the heat surrounding the glass until the temperature of the tea is equal to the surrounding air temperature.

The most important law in thermodynamics associated with cold storage insulated panels is the conductance of thermal energy from the warmer exterior of a cold storage enclosure to the colder interior.

Conductance

Conductance is one of the three methods of heat transfer, and the primary way heat moves through an insulated panel building envelope.

An example of this heat transfer phenomenon occurs in our homes. In the summertime, heat from the outside of a house flows inward where the air conditioning system is working to keep the house cool.

In the wintertime, the heat from inside a house flows outward where it is colder. In each example, the heat is transferred from a higher temperature to a lower one primarily via conductance with the goal of equalizing.

Luckily, our modern age uses high R-value building materials to restrict heat transfer and heating and air conditioning systems that can maintain the desired indoor temperatures.

What is R-Value?

R-value is the thermal resistance rating of a material’s ability to resist heat transfer. Different building materials have drastically different R values, and that determines whether a material works well as an insulator. For example, let’s examine wood-framed polyurethane structural insulated panels used to construct cold storage buildings.

The wood frame has a significantly lower R-value than the polyurethane insulation, thus allowing more thermal energy transfer through it via conduction. But wood frames offer a good structural benefit of connecting panels one to another via a camlock system, thereby creating a structural envelope that can resist major structural forces such as earthquakes, hurricanes, and tornados.

Conversely, polyurethane insulation has a gas-filled cellular structure that significantly reduces heat transfer through its cells and plastic matrix structure via conduction, convection, and radiation, making it a highly effective insulation.

The core comprised of polyurethane insulation makes up the majority of a structural insulated panel – but not all of it. The perimeter structural frame, which holds locking mechanisms that structurally secure one panel to another is comprised of materials that are denser than the polyurethane core foam – such as wood.

A material that is denser more effectively transfers heat energy because its molecules are closer together – thereby conducting heat energy more readily. This perimeter structural frame is considered a thermal bridge as it transfers up to six times more energy than the polyurethane insulation.

WHAT IS THERMAL BRIDGING?

A thermal bridge is a building material that more effectively transfers heat energy than its surrounding materials.

In the case of structural insulated panels, the perimeter frame is a thermal bridge because it more efficiently transfers heat energy when compared to the polyurethane foam insulation. In the case of wood perimeter framing, that rate of transfer is up to 600% greater (6X) than the polyurethane insulation.

While the perimeter frame thermal bridge usually makes up only 10% of the insulated panel surface area, it can account for the majority of the heat conducting through the insulated panel and thus into the inside of the cold storage enclosure.

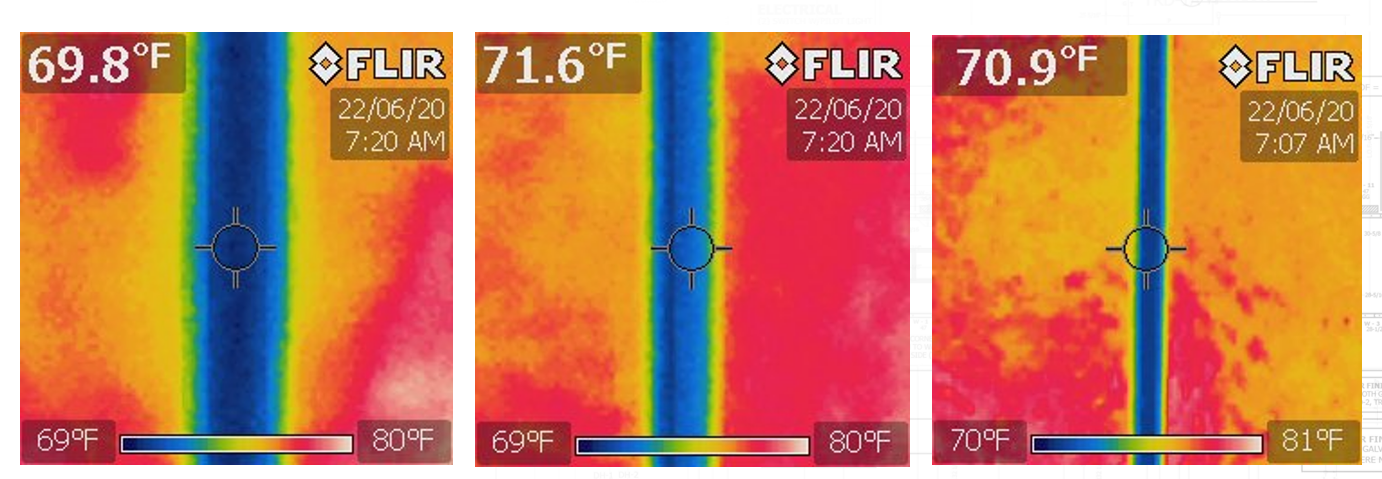

Using a cold storage structural insulated wall panel as an example, the perimeter frame thermal bridge will cause the inside surface temperature of the wall panel in the vicinity of the frame to have a higher temperature than the surrounding polyurethane foam. In an equal but opposite scenario, the same thermal bridge will cause the outside temperature in the vicinity of the frame to have a lower temperature than the surrounding polyurethane insulation.

What Are The Impacts Of Thermal Bridging?

Thermal bridging can cause many issues in the operation of the cold storage system. First in operating costs. The increased inside surface temperature at the thermal bridge will add heat into the cold storage environment that the refrigeration system must remove to hold the set point temperature. Meaning the refrigeration must run longer to remove the additional heat. This uses more electricity and increases monthly electricity bills.

The overall electricity cost impact from thermal bridging in supermarket cold storage rooms can be thousands of dollars per year. Another issue thermal bridging can create is condensation and ice build-up on cold storage building surfaces.

Condensation and icing can occur on the outside of the cold storage structure where the surface temperature has been lowered due to the thermal bridging. Condensation on the walk-in cooler and freezer building surfaces can cause mold development and slippery floors where human health and safety is put at risk.

Condensation can turn to ice in walk-in freezers and cause significant slip and fall hazards. Ice can also form in panel joints of the structural insulated panels due to thermal bridging where it can continue to grow to the point where it destroys the structural integrity of the cold storage building.

How Can Thermal Bridging Be Prevented?

How To Repair Thermal Bridges In Existing Structures

Thermal bridges in existing cold storage structures can be repaired to lessen their impact. There are three cost-effective ways to repair them. Add the missing thermal break, install insulated battens, and add a heat trace.

1. Add The Missing Thermal Break

Where possible adding a missing thermal break is the best option to repair a thermal bridge in an existing structure. This would require cutting a separation into the conductive material, thereby breaking up the transfer of heat.

An example of this is the ceiling panel-to-wall panel connection. A thermal break must be installed into the inside ceiling panel metal skin within the wall space. This thermal break reduces the heat transfer from the outside of the walk-in freezer into the inside via the metal skin.

If the thermal break is missing, condensation and icing can occur on the outside of the freezer at the location of the missing thermal break. A thermal break can be cut into the ceiling metal to eliminate the condition.

It would be cut in the interior ceiling metal skin as close to the wall as possible. An insulated corner batten would then be installed over the cut to reduce heat transfer coming from the outside – resolving the thermal bridge issue.

2. Add Insulated Battens

Adding insulated battens to existing walk-in freezers, lessens the impact of damaged panel joints caused by thermal bridging issues. The insulated battens add an auxiliary layer of insulation with a metal face to disrupt the effects of thermal bridging. It can effectively extend the life of a thermally compromised walk-in freezer for years into the future.

3. Add Auxiliary Heat Trace

For areas severely compromised by thermal bridging in a walk-in freezer, the addition of an auxiliary heat trace beneath an insulated batten can stop condensation and ice build-up. Trace heat is a de-icing heater cable that elevates the temperature of the compromised area above the dew point temperature, thereby drying out and stopping condensation and ice. It has commonly been used on the perimeter of freezer floors, between wall panels, and at wall-to-ceiling connections. KPS Global can engineer and install custom heat trace solutions to meet even the most demanding conditions.

What Is A Thermal Break?

A thermal break increases the path of resistance of heat flow in a thermally conductive material, significantly reducing energy transfer. In cold storage building envelopes, thermal breaks are intentionally placed within the cold storage building envelope to reduce the thermal conductivity between the interior and exterior environments.

They are used to break up heat transfer in the insulated building envelope at all connection points such as ceilings to walls, and walls to floors. They are especially important in freezer environments as more heat energy can transfer into the inside space.

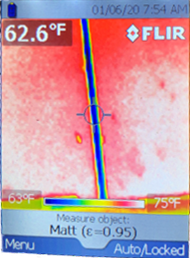

One of the key thermal breaks in the freezer walk-in envelope is one between the outside floor and the inside floor of the freezer.

The thermal break must completely isolate the freezer floor from the building floor around it. If missing, condensation and ice will form on the building floor around the outside perimeter of the walk-in freezer. This will create both a human health and safety hazard.

Conclusion

Insulated panel solutions by KPS Global are engineered and manufactured to maximize the operating efficiency of the enclosed space. By creating thermal breaks, we can minimize the adverse effects of thermal bridges. By understanding thermodynamics and utilizing thermal breaks and other approaches, KPS Global can mitigate thermal bridging in cold storage enclosures providing its customers with highly efficient controlled environments. Contact the experts at KPS Global to help solve issues from thermal bridging.