Article first featured on Convenience & Car Wash Canada. Click here for the original article.

Walk-in coolers and freezers are expensive pieces of equipment that often work harder than necessary to counteract the negative effects of damage from the daily abuse they take. The impact of carts or pallet jacks, as well as condensation and icing from challenging environmental conditions, can cause a walk-in to experience a lot of wear and tear. This article will explore situations when repairing a walk-in cooler or freezer is a viable option and a way to extend the life of your unit, as well as situations when it might be better to replace the entire walk-in. There are several factors that must be considered before making that decision.

WALK-IN COOLER REPAIR

The average lifespan of a walk-in cooler or freezer is 10 to 15 years depending on the conditions it is exposed to. Below is a list of situations in which repairs can or should be made to your walk-in:

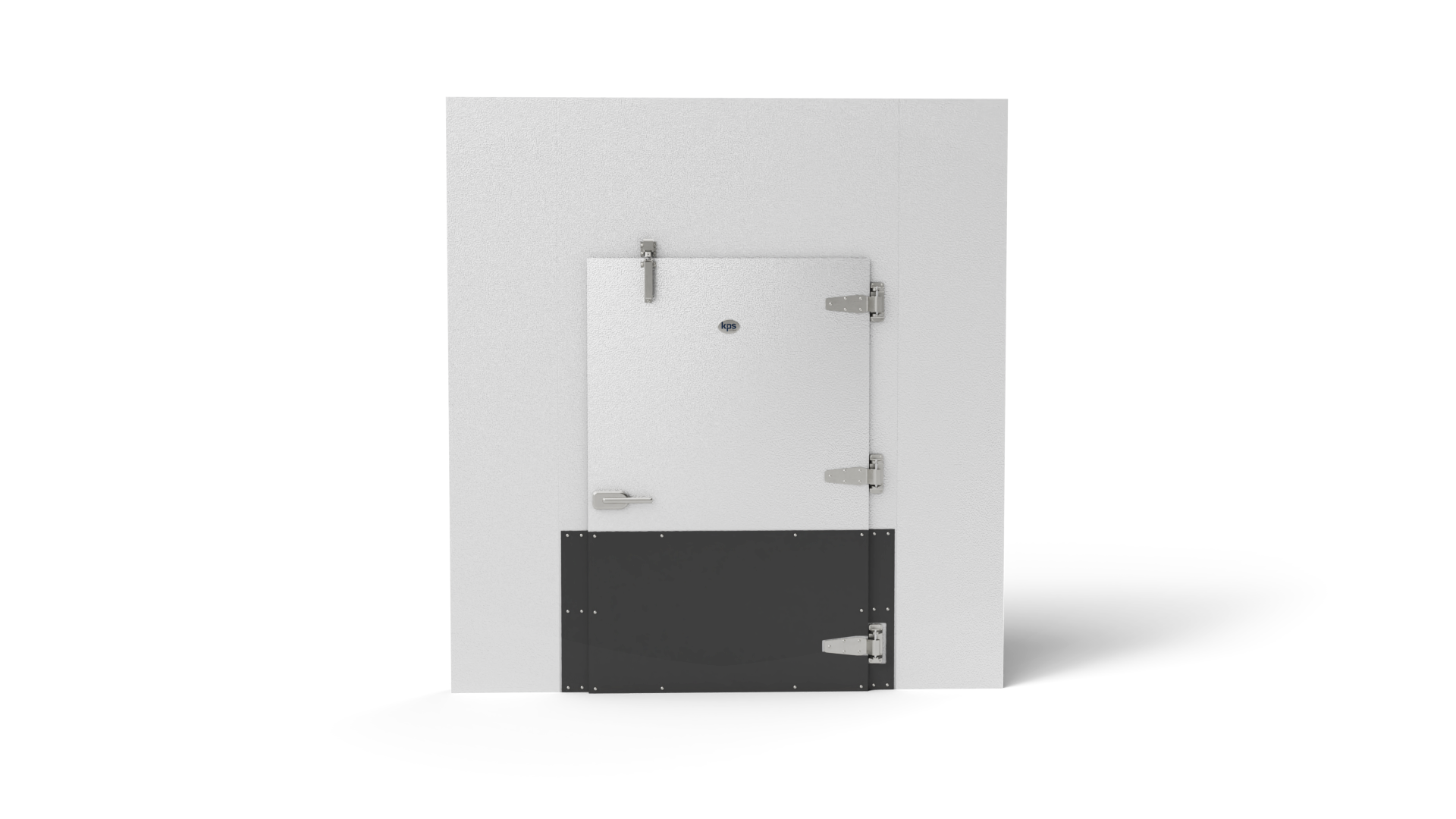

- Walk-in Door

- The door isn’t closing.

This is a common issue as walk-in cooler doors and hinges take most of the wear and tear. Adjusting or replacing the door hardware is a low-cost solution.

- Ice or condensation has formed on the door frame of your walk-in cooler or freezer.

Replacing the door perimeter and sweep heater or checking its electrical connections will likely be a fix.

- Perimeter of Your Walk-in

- You notice puddles of water on or near your walk-in.

Water puddling is a sign of thermal-conductivity issues. Poorly sealed panel joints or thermal bridges across walk-in panels can create condensation on surfaces that will collect into puddles of water. Depending on the cause of the thermal bridging, repairs can be made to eliminate the condensation issues. Insulated battens can be added to panel joints that seal poorly as a way to stop the condensation. Spray-foam sealants can be added to fill gaps around refrigeration piping, electrical conduits and in open joints to stop cold transfer and the condensation it causes.

- Your unit is making loud or unusual noises.

This often signals an issue with the evaporator. Most frequently, loud noises from the evaporator are caused by ice buildup on the coil where it comes into contact with the fan blades. This ice buildup is often caused by defrost settings or defrost heater equipment issues that can be adjusted or repaired. Another frequent cause is humid air infiltrating through a walk-in door that is either being left open for extended periods of time or where there are gaps in the door seal or door sweep.

- Walk-in Panel Joints

- Condensation, frost and ice are building up on your panel joints or the joints are swollen or displaced.

These issues arise when water vapor penetrates the panel joint where it condenses into liquid water inside the joint. If the walk-in is a freezer, that condensed water can freeze, creating ice. You will see the joint is separated by the growing ice, eventually causing the affected panel joints to swell and separate, ultimately causing damage and increasing operating costs. The application of batten strips or thermal liner panels can resolve this issue.

- Exterior panel joints are sweating.

In some ambient conditions, the combination of temperature and high humidity is such that having wood-framed panels or an inadequate R-value (the insulation’s ability to restrict air flow into a walk-in cooler or freezer) can be the cause of this issue. It will be beneficial to move to a frame type and/or thicker panels that are designed to operate in those conditions. Batten strips and liner panels can provide relief from a frame that is performing poorly thermally.

- Walk-in Panels

- Your panels display white rust or corrosion.

Reskinning the interior by applying thermal liner panels addresses this issue and increases the insulative properties of your walk-in panels.

- You have minor damage to a panel.

In this case, a patch or replacement of the affected panels is a solution.

- The panel joints are separated or have opened too far for repair.

This condition can be repaired by removing ice in the joint with a strip heater, filling the gap with a spray-foam insulation and then a covering the joint with a batten strip.

- Panel walls are bowing or the ceiling is bowing/caving in.

In such a condition, a structural support system can often be installed to remediate the condition.

- Existing panels may not be meeting current energy codes.

The addition of thermal liner panels will increase the insulative properties of your walk-in panels by up to R-13.1 per inch of thickness.

- Floor

- Your freezer floor is heaving due to water getting under the walk-in and freezing.

In this case, a new “drop-in” floor can be installed between the existing walls to resolve the issue and create a long-term solution.

WHEN TO REPLACE YOUR WALK-IN

There will be a point at which repair is not economical or feasible. Delay in addressing the issue may result in a sudden breakdown, which is not ideal.

New units offer more energy efficiencies as new panels have better insulative properties and higher R-values. Having a high R-value at the panel framing is critical since walk-ins constantly fight to keep warm air and humidity from making their way into the unit.

Making the Call

Having an ongoing preventative maintenance program (conducting routine inspections, keeping the unit clean and maintaining humidity levels surrounding the walk-in) can not only extend the unit’s longevity but also uphold its ability to operate efficiently.

However, as issues arise it is important to address them as quickly as possible. Problems can start out small and develop rapidly.

Repairing where possible will save you money. However, if the cost of your repairs is mounting or the unit is not repairable, investing in a new unit will likely be necessary.

In summary, when making the decision to repair or replace your walk-in cooler or freezer, consider the age of your unit, the cost of repair versus replacement, the temperature consistency of your system, the amount of energy the unit is consuming and the frequency of your preventative maintenance. Once you’ve checked all these boxes, you can make your decision with confidence.

Jason Bratcher is the senior manager of project management at KPS Global. With over 20 years of professional experience in the cold storage industry, Bratcher leverages his extensive knowledge to lead the company’s construction services department, which delivers seamless installation services for projects of all sizes. Under his direction, his team handles all the phases of a walk-in project, from start to finish.