Businesses that operate walk-in coolers and freezers often face challenges with the units with respect to their expense, maintenance, and efficiency. The latter is of critical importance, because not only does energy efficiency correspond directly with cost and performance, it is also subject to government regulations that must be adhered to in order to remain compliant with federal law. KPS Global is here to help with navigating walk-in cooler and freezer regulations.

The specific legislation in question is the 2009 Energy Independence and Security Act (EISA), which establishes minimum energy efficiency requirements for walk-in cooler and freezer panels, doors, refrigeration and lighting. The EISA was crafted with the intent of improving energy efficiency within many industries, including refrigeration. However, ever since the law’s inception, there has been some uncertainty surrounding the regulations, particularly, with conflicting R-value calculations.

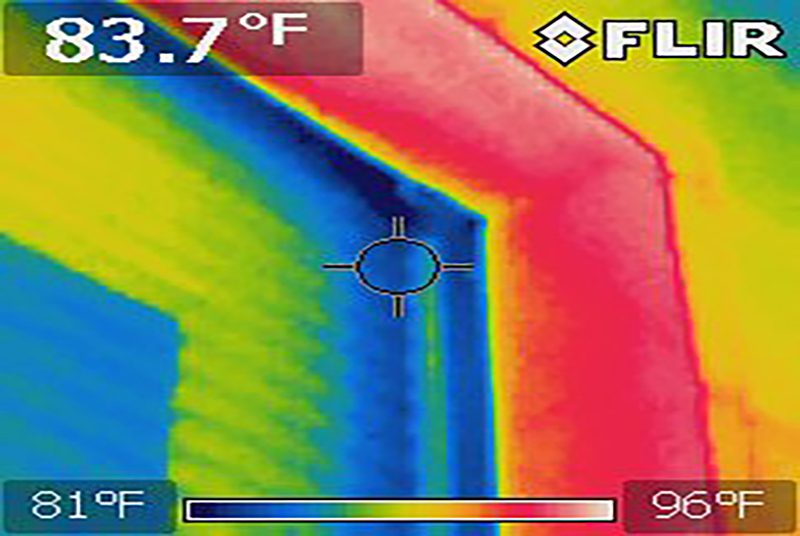

The R-value is the capacity of an insulating material to resist heat flow. A higher R-value corresponds with greater insulating power. Part of the confusion regarding the R-value calculations stems from the fact that while the Department of Energy (DOE) is responsible for administering the regulations in the U.S., the International Code Council’s International Energy Conservation Code (IECC) also has its own different R-value standards. The IECC specifies a minimum insulation value of R25 for cooler and freezer walls/ceilings, and R32 for non-glass doors, while the DOE specifies a minimum insulation value of R25 for cooler walls and ceilings, R32 for freezer walls and ceilings, and R28 for freezer floors. Additionally, DOE requires a minimum R-value of R25 for cooler non-glass doors and R32 for non-glass freezer doors.

The EISA/DOE details other provisions that refrigeration equipment must meet to help optimize energy efficiency. Walk-ins are required to have strip doors, spring hinged doors or another method of minimizing infiltration when doors are ajar. Walk-in doors must contain automatic door closers that firmly shut, except if the doors are wider than 3’9” or taller than 7’. Interior lighting must contain 40 lumens per watt. However, light sources with an efficacy of 40 lumens per watt or less may be used in conjunction with an automatic timer that deactivates the lights after 15 minutes of non-occupancy. There is also a mandate that double-pane glass used in coolers is heat-reflective treated and gas filled. Also acceptable is triple-pane glass with heat-reflective treatment. When it comes to freezers, triple-pane glass that is either heat-reflective treated or gas filled is acceptable.

The 2009 EISA contains the first regulations of its kind that attempts to create energy efficiency standards for walk-in coolers and freezers. Each supplier within the manufacturing chain is responsible for ensuring their product (glass doors, refrigeration, strip doors, etc) is EISA-compliant. While the provisions of the law may seem inscrutable, KPSG assures customers that its insulated panels and manufactured doors deliver superior performance while meeting the specifications of government guidelines. Engineered with over half a century of experience in the design, our products represent the best in the industry.

Learn more about our offerings by visiting our website today!