When you need to extend the life of your walk-in but replacement isn’t an option, an alternative exists in Thermal Liner Panels. Thermal liner panels act as a sort of wallpaper that is affixed to the interior of the unit, improving the thermal performance of the walk-in cooler or freezer.

Food-storage areas, such as walk-in coolers or freezers, often come with the kind of high humidity levels that create an environment where rust and bacteria run rampant. A rusty, discolored walk-in is not only unpleasant to behold, but panel corrosion within cold storage also affects unit efficiency and can lead to food safety violations that may result in hefty fines or the temporary closure of an establishment—meaning lost operation days, decreased revenues and a marred reputation with clientele.

But what if your budget doesn’t allow for a new walk-in, or the downtime entailed in a replacement affects your ability to operate at normal capacity, delaying product availability and requiring additional cold storage while the existing walk-in is torn down?

KPS Global, the industry-leading manufacturer of walk-in coolers and freezers for convenience and grocery stores, foodservice, big box retailers, has a solution—Thermal Liner Panels.

Reconstructing Years of Damage

The panels of your walk-in cooler and freezer take a lot of “heat,” so to speak. Normal daily wear and tear, panel discoloration, staining and corrosion caused by humid conditions, impact by carts, lifts or pallet jacks, and condensation and icing can lead to to irregular interior temperatures, an environment unsuitable for cooler to freezer product conversion and elevated energy costs.

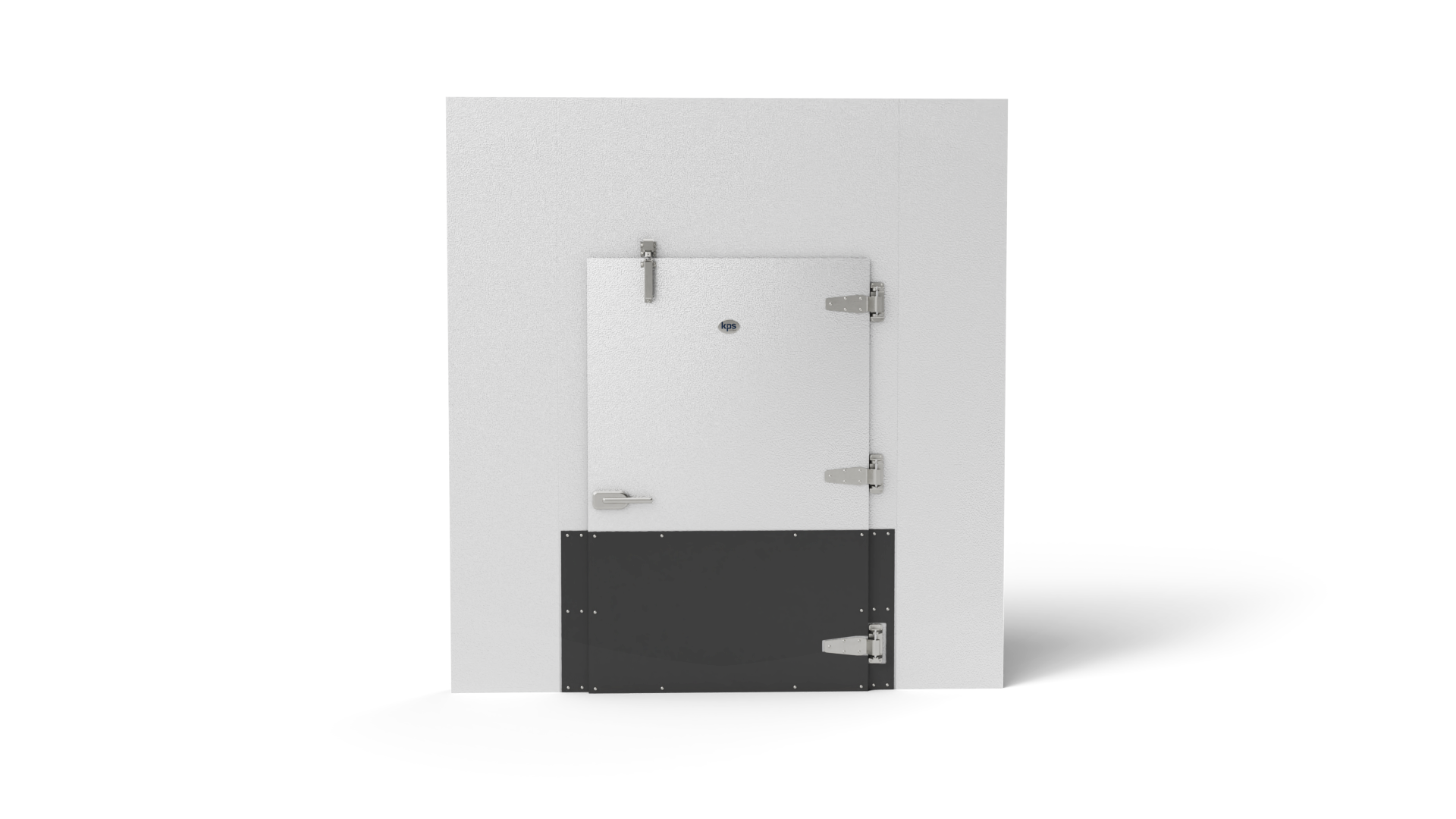

Designed to reface and insulate existing insulated cold storage panels, thermal liner panels from KPSG not only improve panel appearance and increase performance, but can also increase the lifecycle of your existing walk-in by up to five years. But how do they work?

A Non-Invasive Cold Storage Facelift

Constructed of a durable panel face material bonded to an insulated core and attached by a proprietary strip assembly system that includes an integral gasket seal, KPSG’s thermal liner panels are a non-invasive, easy-to-install solution.

They simply wrap the existing panels to provide an aesthetically-pleasing additional layer of insulation that adds an additional R-value of 5 to your current unit.

Offering textured or smooth finishes in a variety of colors with panel facers in either embossed aluminum-zinc alloy steel or embossed aluminum fiberglass reinforced plastic (FRP), our 47” wide panels are available in both ¾” inch and 2” thicknesses and in 10’ or 12’ lengths that are field cut according to exact project specs, enabling a customized fit over your existing walk-in panels—even for most non-KPSG cold storage units.

When compared to a total cold storage replacement, KPS Global thermal panel liners are the quick, cost-effective alternative that helps owners comply with health code standards, saving you headaches, time and money while extending the life of your walk-in.

Check out the before and after pictures, watch the step-by-step how-to video and learn more about our thermal panel liners. Ready to see the difference in action? Request a quote today.